The train line that runs between Athens and Piraeus is an 8 km stretch, with a journey time taking about 20 minutes. The port city of Piraeus, which roughly means ‘the place of passage’ is one of the largest passenger terminals in Europe. Serving about 20 million tourists a year, many catch the metro to get into Athens. Heavy freight trains run on these lines too, since the nearby container port is not using its dedicated rail freight line alone.

Essential to this project therefore was to ensure that the three level crossings along the route operate reliably and, most importantly, safely. In this southern region of Greece, the average high temperature is 35 degC. In trackside equipment cabinets they can reach 60 degC or more. Therefore, the ability for the level crossings to remain fully-functional in these extreme temperatures was another critical factor to consider.

The original barriers at each of the level crossings were hand-operated. With so many trains passing though, day and night, this was neither effective nor safe. An essential upgrade was identified and AKTOR was asked to lead the project. As an international, highly diversified company, AKTOR was keen to ensure that whatever it developed it had to be without vendor lock-in. The new level crossing in the ERMIS LX project is equipped with powerful safety controllers from HIMA. The result: Full insight of barrier status and rail/road signal control for vastly improved safety, as well as increased frequency and therefore passenger capacity.

No vendor lock-in

Together, they worked on the design of the safety technology. The goal was to develop a signaling solution that complies with the SIL4 safety level according to CENELEC and install it directly on the tracks. The solution: modern COTS safety controllers from HIMA. For this project, the HIMatrix controllers were used with extended temperature ratings.

Instead of going down the proprietary route, AKTOR turned to HIMA which gave the company the flexibility to develop a solution that is also suitable basis for future projects. By writing its own code from the ground up, a set of function blocks were created that will be used and further developed, ensuring continuous improvement.

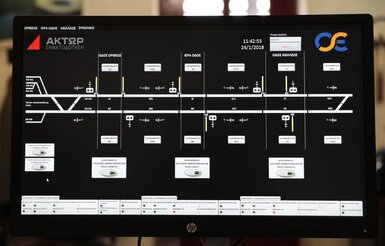

AKTOR has developed a monitoring system called ‘ARTEMMIS’, which collects all the data from the trackside equipment and displays their status on a monitor in real-time. Furthermore, the station master is able to send commands via this system to perform certain functions – such as closing the barrier in an emergency situation.

“Many of the specialist suppliers of interlockings do not support peripheral components from other vendors,” explains Athanassios Zacharatos, Signaling Project Manager at AKTOR. “This can make it quite expensive and sometimes the system is not flexible enough to meet the desired requirements. The ERMIS LX project is the first time we had used HIMA safety controllers, which are lower-cost COTS products with no vendor lock-in. With everything taken into account, including cost-savings achieved by being able to shop around for peripheral components, we’d estimate a saving of 40%. And, because they comply with CENELEC SIL4 and have already been tested in the field in numerous and varied safety critical applications, we were confident of a robust and reliable solution.”