#safetygoesdigital

Funktionale Sicherheit in der digitalen Transformation

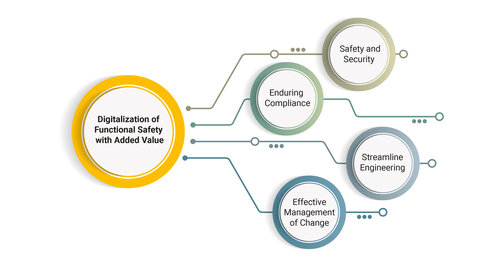

Digitalisierung kann Anlagenbetreibern und Anlagenerrichtern einen echten Mehrwert bieten: Mehr Sicherheit und gleichzeitig weniger Aufwand und Kosten. Wir helfen Ihnen, das Potenzial der Digitalisierung voll auszuschöpfen. Dabei verfolgen wir nur ein Ziel: Ihren Nutzen. Die Basis ist unsere bewährte Safety Platform. Mehr erfahren

Vielen Dank an alle, die für uns gestimmt haben. Wir sind mit dem HIMA Smart Safety Test Gewinner in der Kategorie MSR/Automation der Best of Industry Awards 2023!

Empfehlungen

himalaya – HIMA’s Innovation Lab

Exploration rocks! himalaya, das HIMA Exploration Lab fungiert als Inkubator für neue Geschäftsmodelle. Wir erforschen neue Wege zur Risikoreduzierung für Unternehmen und Menschen.

HIMA Academy

Die Anforderungen an die Sicherheitsstandards in Ihren Anlagen und in Ihren Systemen steigen. Verfügen Sie über alle Qualifikationen, die Sie für den Betrieb und die Wartung Ihrer Anlagen benötigen? Die HIMA-Akademie bietet Ihnen ein umfassendes Angebot an Schlüsselseminaren.

Sicherer und effektiver Einsatz im Feld

Feldgeräte sammeln eine enorme Menge an Daten. Doch wie können Sie das Potenzial dieser Informationen nutzen? Die HART-Lösung von HIMA ermöglicht Ihnen eine sichere Kommunikation über das etablierte HART-Protokoll bis SIL 3. Damit können Sie die Daten der Feldgeräte nicht nur für die einfache Parametrierung nutzen.