Introduction

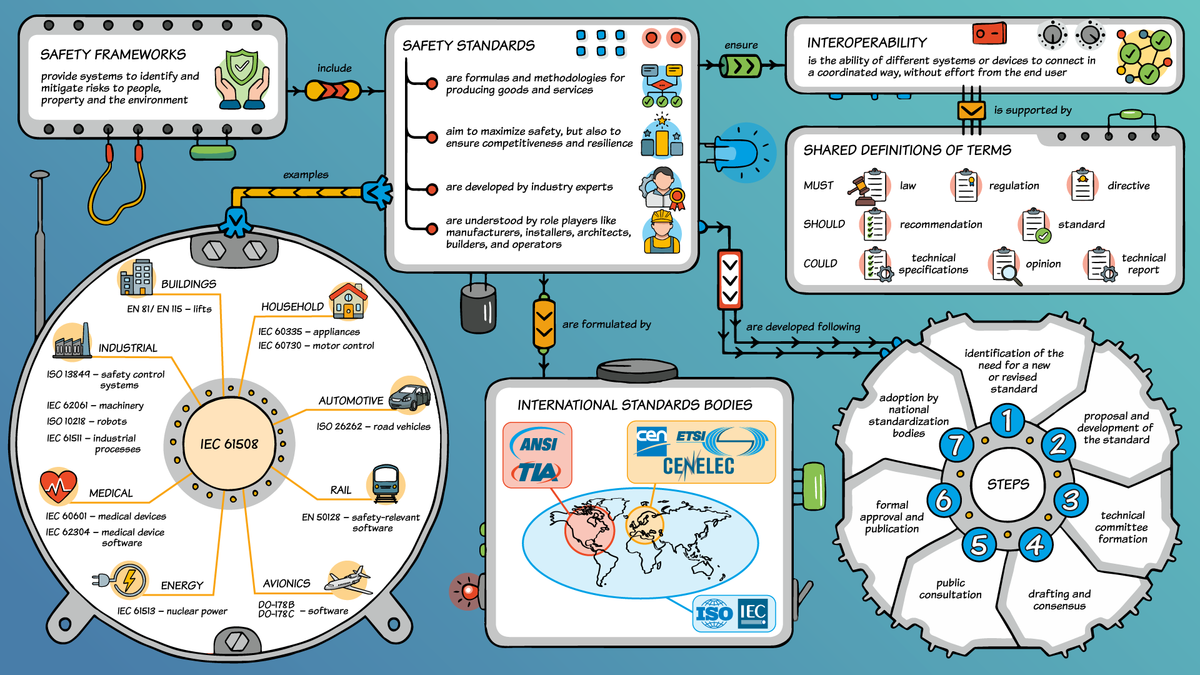

For societies to be safe, systems known as safety frameworks are essential. These safety frameworks normally include safety standards and regulations that combine to make the places in which we live and work safer.

In such a vast area as safety, it is important that all the role players involved in manufacturing and deploying products and equipment understand how to act as one. In this chapter, we will focus on standards as one of the most important aspects of ensuring the continued safety of equipment and systems around us.

As described in Figure 1 below, the success of safety initiatives can be measured according to outcomes such as the number of incidences of injury or death. Having standards that everyone adheres to plays a major role in this.

When societies successfully implement safety mechanisms that impact the behaviors of ordinary people, these safety frameworks have a positive effect on safety results.

Fig 1. Systems of safety based on IEC white paper: Safety in the future, 2020

Source: HIMA Paul Hildebrandt GmbH

1 Safety frameworks

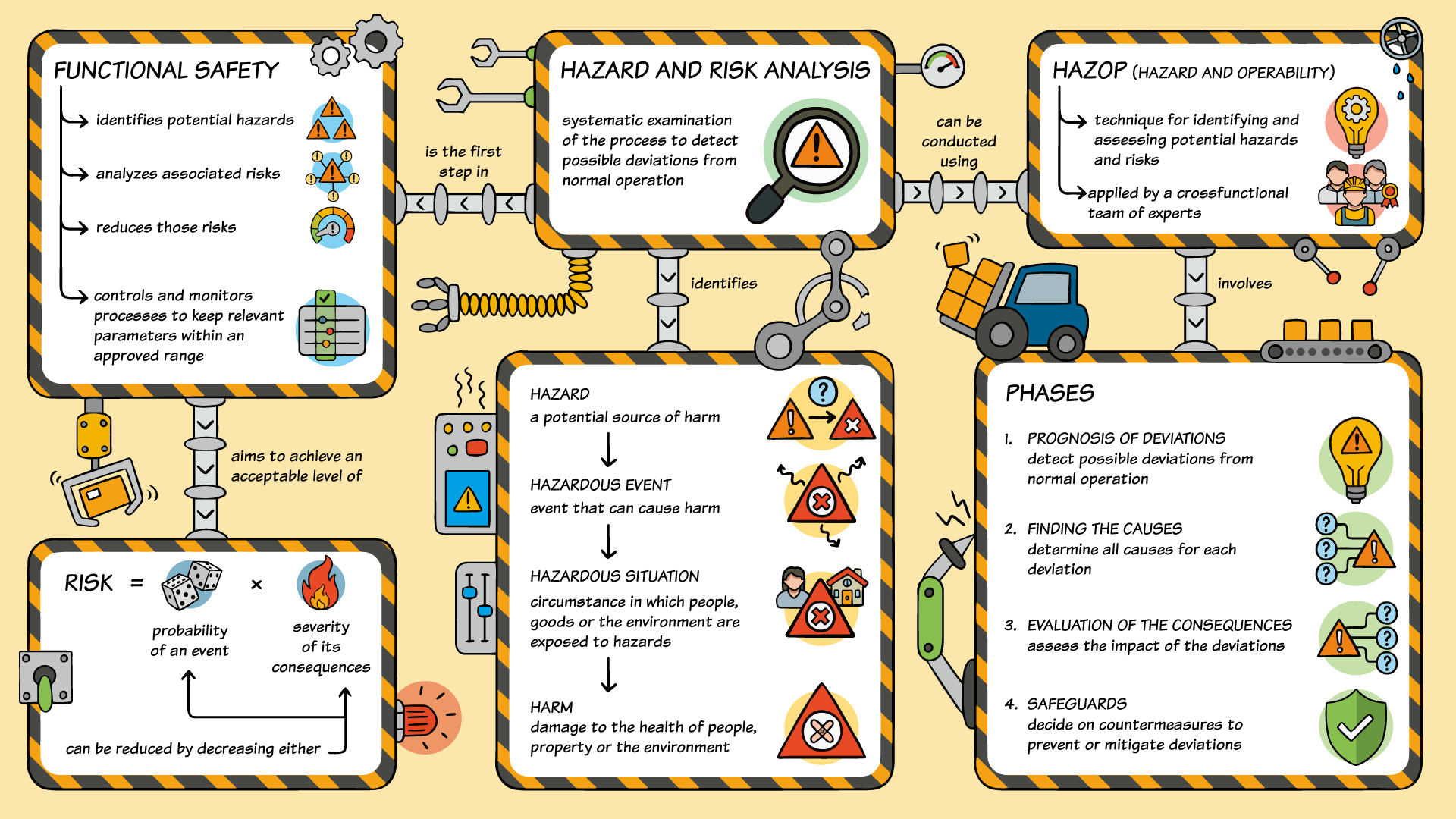

A safety framework is a systematic approach to enhancing safety in various domains, especially where the safety of people, property, and the environment is a critical concern. Some examples of these domains include the process and manufacturing industries, to name only two. Safety frameworks are intended to provide more comprehensive systems to identify and mitigate risks and hazards.

In many countries, safety frameworks are meant to deliver policies and implement practices that prioritize the safety of human life and physical assets. These frameworks are an important way of preventing injuries and creating a safe environment.

For example, when it comes to road safety, governments have realized that in addition to strong traffic law enforcement, it is also necessary to implement a holistic urban safety framework that raises driver awareness. It starts with meticulous traffic planning, well-designed transportation infrastructure, and thoughtful urban development.

A crucial aspect of safety frameworks involves the implementation of a robust system of standards that are backed up by appropriate laws and regulations. This means that even though standards in most cases are simply recommendations, they can be codified into law for the benefit of end users.

For this reason, standards must be well-understood by role players like manufacturers, installers, architects, builders, and operators. Standards specify explicit requirements that ensure the utmost safety for everyone involved. There are independent standards bodies operating at international level that provide standards which can be adopted at national level. Standards must provide clear guidance on how every role player in a certain domain can operate in a manner that prioritizes safety.

For instance, it is unimaginable for someone to start constructing a building without adhering to established city standards. Across the globe, every country has established construction standards with the aim of creating safer living spaces. Similarly, product safety standards play a vital role in guaranteeing that products and systems are designed to minimize risks. Every appliance or piece of equipment in our homes and offices has been manufactured according to stringent standards.

Figure 2: It is illegal to start an unapproved construction project that does not abide by construction safety standard

Source: Adobe Stock

By enforcing a comprehensive system of standards, individuals are protected from unsafe products and hazardous environments. These standards, if adopted by the relevant national authorities, can become legal requirements that call for compliance from all parties involved in the manufacturing process. Standards, and their consistent adoption, play a vital role in ensuring we can all go about our lives safely.

2 Overview of the role of standards

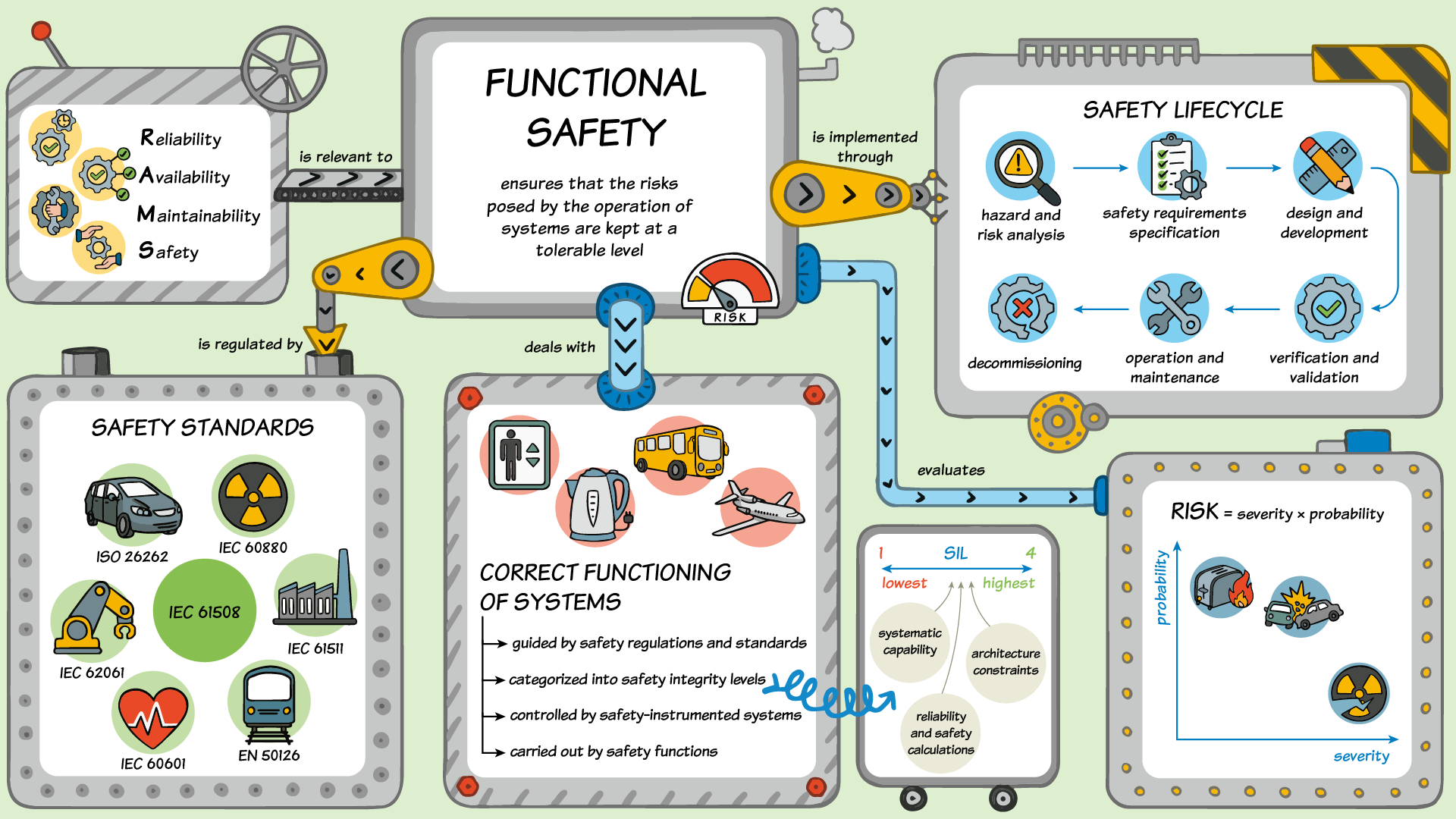

Standards are formulas and methodologies for producing goods and services, developed by experts in their respective fields. They are technical in nature, meaning that in the realm of manufacturing physical goods such as electrical items, they concern themselves with the conditions, characteristics, and compatibility of constituent parts. Standards also encompass a set of criteria that govern the proper functioning and execution of operations within specific industries.

One of the most important objectives that standards seek to achieve is interoperability. This term is defined as the ability of different systems or devices to connect and communicate in a coordinated way, without effort from the user.

Interoperability is especially required when products or systems are used by many stakeholders such as manufacturers, operators, and consumers across various geographies. In turn, if these products or systems are many in number, their sheer volume requires a common working language. Also, if the same products or systems have many use cases, this adds an extra layer of complexity.

To avoid silos within organizations and stakeholder groups that could hamper interoperability, it is necessary to arrive at commonly agreed upon definitions. As demonstrated in Figure 3, experts in Functional Safety and beyond call for shared definitions of terms, unique identifiers, and a standard exchange format.

Figure 3: The three pillars of standardization

Source: HIMA Paul Hildebrandt GmbH

Standards are the culmination of the knowledge and expertise gained by individuals who have dedicated considerable time to working in their professional fields. These individuals can include technical experts from manufacturers, trade associations, and regulators.

Figure 4 illustrates the extensive application of standards in promoting safety and ensuring positive outcomes for a multitude of individuals. Throughout this section, we will explore some standards, with particular emphasis on Functional Safety.

Figure 4: The role of standards

Source: HIMA Paul Hildebrandt GmbH

3 Common terms in the world of standards

To begin with, standards are merely recommendations on technical specifications from experts within a field. Although they start out as recommendations, standards often take their place within the regulations and laws of countries because authorities see the important role they play in ensuring safety. As such, standards are often discussed in legal terms if though, by definition, they are technical in nature. Before we go on, let us cover some of the most used terms in the context of standards.

We should note that all the terms in this section have definitions which can, and often are, applied in other subject areas outside of safety, and within broader society itself. However, as this chapter is concerned specifically with safety standards, it is with this lens through which we discuss the terms.

In fact, on the subject of definitions, not even the experts themselves universally agree on the exact definition of words. When looking up the meaning of a common term such as ‘standards’ as defined by the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO), the definitions are broadly similar but contain slightly different emphases by each organization.

3.1 Regulations and directions

3.1.1 Regulations

Regulation is a common word that may have many applications. Taking a top-down view, governments can issue regulations as part of legislation. Within industries, regulations refer to the applicable rules to be followed by industry members. Even companies can have their own regulations. When we refer to regulations in this chapter, we refer to a binding legislative act or rule issued at national level.

Regulations are designed to govern the conduct of individuals, businesses, or organizations. For example, in Europe, it is the EU’s job to lay out a detailed set of rules that provide specific requirements within many domains in society. Regulations aim to clarify broader legislation by providing more specific instructions on how the law should be applied in the real world.

For example, when the EU began trying to legislate the protection of consumer data in the 1990s, it first came up with a broad legal framework on how consumer data should be handled. This framework explained the overarching rationale for implementing consumer data management and potential penalties for transgressors. However, it still had to issue clear regulations that included specific examples of when, how, and by whom data should be handled, culminating in the General Data Protection Regulation (GDPR) which came into effect in 2018 and laid out strict compliance and enforcement measures.

Figure 5: The EU issues regulations and directives in respect of standards in Europe.

Source: Adobe Stock

3.1.2 Directives

As we have mentioned, some terms in this section are common words with several interpretations depending on who is using the word. In the context of standards covered here, a directive is a legal instrument issued by a legislative body to set out specific objectives that must be achieved by its members. In the case of safety directives issued by the EU, they provide instructions for member states to incorporate the directive's provisions into their national laws within a certain timeframe.

Directives are typically used in areas where the harmonization of laws and regulations across different jurisdictions is necessary to ensure a consistent approach or achieve common goals. Harmonization is simply the process of eliminating redundant or conflicting standards which may have evolved independently.

Directives in the sense in which we refer, do not have immediate legal effect. Instead, they require member states to enact domestic legislation to implement the directive's provisions into their national legal systems within a timeframe.

It is up to the individual countries to devise their own laws on how to reach these goals. One example of a directive is the EU’s single-use plastics directive, which reduces the impact of certain single-use plastics on the environment by reducing or even banning the use of single-use plastics such as plates, straws, and cups for beverages.

Once a directive is transposed into national law, it becomes binding on the member state, as well as individuals, businesses, or organizations within that jurisdiction. Figure 6 demonstrates the role played by EU directives and how they are implemented into national laws.

Figure 6: Relationship between national standards and laws in the EU

Source: HIMA Paul Hildebrandt GmbH

3.2 Standards and norms

3.2.1 Standards

A standard refers to a collection of regulations as agreed upon by industry experts. Standards serve as benchmarks by which performance or outcomes can be measured. They encompass aspects such as dimensions, tolerances, material properties, manufacturing methods, and other important parameters.

Typically, standards are established by experts in a particular field, drawing upon existing industry practices and knowledge. Their purpose is to guarantee consistency of outcomes if they are followed. They provide a framework, which, if observed, will minimize errors, and ensure compatibility and interoperability of parts and products.

In Functional Safety, standards are far-reaching. They have implications in every manufacturing stage including risk assessment, hazard analysis, safety requirements specification, design guidelines, verification, and maintenance procedures. They outline the necessary steps, methodologies, and processes to be considered by manufacturers and users of products that must be created safely. As demonstrated in Figure 7, standards organizations play a major role in crafting and updating standards around the world.

Figure 7: Standards organizations as enablers for societal progress

Source: HIMA Paul Hildebrandt GmbH, based on IEC white paper: Safety in the future, 2020

3.2.2 Norms

Here it is necessary to give some attention to the semantic differences between standards and norms. When using these words in a technical sense, they can sometimes be interchangeable.

In Germany we can find reference to Normen und Standards with significant overlap between the words.

In the British standardization context, standards is the prevailing word, while norm is used in social contexts.

In French standardization environments, we usually find the word norme with mention of standards being rare.

We will not spend too much time in this linguistic rabbit hole, except to say that the two words can be used interchangeably or on their own.

3.3 Technical add-ons

3.3.1 Technical Report

A technical report, in a broad sense, is a document that describes the process, progress, or results of technical research or the state of a technical or scientific research problem. In the context of standards, a technical report is a document that provides detailed information such as analysis or guidelines on matters related to a standard. Technical reports can cover a wide array of subjects. Some examples of this include industry trends, research findings, and experimental data.

A technical report is normally drafted by a technical committee or working group of subject matter experts. Technical reports are meant to provide stakeholders like manufacturers, engineers, regulators, and users with a deeper understanding of the technical aspects covered by the standard.

Standards are usually voluntary and, in this sense, non-normative, although they may also become mandatory in specific cases. Technical reports are most often non-normative, partly because they are not normally peer reviewed, and are much less likely to become mandatory requirements like the standard itself. Rather, they serve as supplementary information to support the understanding and application of the standard.

3.3.2 Technical Specification

According to the IEC, a technical specification is a:

Type of normative document and standard…(a) document that prescribes technical requirements to be fulfilled by a product, process, or service. A technical specification should indicate, whenever appropriate, the procedure(s) by means of which it may be determined whether the requirements given are fulfilled. A technical specification may be a standard, a part of a standard or independent of a standard. [ISO/IEC Guide 2:2004]

Therefore, a technical specification is a document that provides detailed requirements, specifications, or guidelines for the manufacture of a product. The document can also cover additional areas such as the design, development, or testing of that product.

Technical specifications are typically created by subject matter experts within standards organizations or industry associations to make sure that everyone in the industry has access to important common information.

Technical specifications define the parameters and tolerances that a product or process must conform to meet its use case. In this sense, a specification is driven by the needs of the end user. It covers areas such as measurements, materials, and dimensions to achieve uniformity with the standard.

3.4 Decisions

While a decision can be made by any person in any walk of life, in the context of the enforcement of standards, so-called “decisions” are used by organizations like the EU to address specific issues or situations that require immediate corrective action. They can be targeted at individuals, companies, or even member states themselves, and they have a binding effect on those to whom they are addressed.

For example, the European Medicines Agency (EMA), which is the EU's regulatory body responsible for the supervision of medicines, has in the past imposed significant fines on pharmaceutical companies for failing to comply with safety regulations.

The decision could be based on a company's failure to adequately monitor and address the potential safety risks associated with one of its medications. A decision, in this case, would seek to hold the company accountable for its safety breach, discourage similar non-compliance in the industry, and reinforce the importance of standards.

3.5 Recommendations and opinions

3.5.1 Recommendations

A recommendation is a statement by a legislative body intended to make its views known and to suggest a line of action without imposing any legal obligation on those to whom it is addressed.

One example of this is the EU's recommendation on cybersecurity for the Internet of Things (IoT) devices. In 2019, the EU issued a set of recommendations to enhance the security and resilience of IoT devices. The recommendation did not have any legal consequences but allowed concerned organizations to modify their security stance at their own pace.

Figure 8: Safety agencies such as EASA can issue opinions

Source: EASA Logo, als gemeinfrei gekennzeichnet, Details auf Wikimedia Commons

3.5.2 Opinions

An opinion is an interpretation of a matter issued by an organization. Opinions are typically, though not always, issued at organizational, industry, or regulatory level.

They are non-binding. In the context of safety, an opinion could simply be the statement of the collective position of a regulatory or legal body on a specific issue. For example, a safety body such as the European Aviation Safety Agency (EASA) could give an opinion on the use of artificial intelligence in aeronautics systems. As we can see, opinions in this sense are statements issued by concerned authorities on matters related to their field.

4 How are standards developed?

There was a time not that long ago within the EU when each country published its own standards. In recent times, there has been a coordinated push towards shared standards, which is why we

find much more harmonized regulations on the continent.

During the time when they operated independently, every member country already had one or more of its own standards institutes. At European level, as legislation has become more uniformly applied, there has been an increase in cooperation. This cooperation now includes the EU, international bodies like the IEC and ISO, as well as national standards institutes, such as Deutsches Institut für Normung (DIN), which is the German national organization for standardization. The relationship is explained in Figure 9.

Figure 9: Links between international, European, and national standards bodies

Source: HIMA Paul Hildebrandt GmbH

4.1 Important standards bodies

The International Electrotechnical Commission (IEC) is primarily concerned with electrical and electronic issues. It is focused on ensuring quality infrastructure and international trade in electrical and electronic goods. The IEC has a membership of over 170 countries, and it covers more than 10,000 standards.

International Organization for Standardization (ISO) is an independent, non-governmental international organization with a membership of 168 national standards bodies. It develops voluntary, consensus-based international standards.

The European Committee for Standardization (CEN) brings together the national standardization bodies of 34 European countries. It provides a common platform for the harmonization of European standards and other technical documents on various types of products, services, and processes.

The European Committee for Electrotechnical Standardization (CENELEC) is responsible for developing voluntary standards for electrical and electronic engineering within Europe. It focuses on standardization in the field of electrotechnical engineering and works to facilitate the coordinated development of standards among European national electrotechnical committees.

4.2 Overview of the steps involved

The life of a standard normally starts with technical experts identifying a need for a new or revised standard. This could be driven by technological change, industry needs, or regulatory requirements. In Europe, the process starts when the EU formulates general safety objectives via directives and regulations. These safety objectives are overarching in nature and need to be specified more precisely in the form of standards.

At European level, an independent international body such as the ISO or IEC will be nominated to play the role of a conductor. Even so, the EU might not accept the proposed standards and it will be up to the international body to apply amendments. This was the case with IEC61511, Ed. 2, which was released by the IEC in 2016. CENELEC did not accept some of its prescriptions and did not adopt it. Only after a Corrigendum (correction) was released by the IEC board in 2019 was accepted and adopted as an EN and DIN standard.

Standards are the result of a long, considered, and expensive process. It takes many experts diligently working together to develop a standard. It is not uncommon for experts with deep expertise in the same area to differ on certain matters during the formation of standards. However, most times, consensus is reached through robust engagement. At EU level, the development of standards normally includes the following steps:

- Proposal and development of the standard

- Technical committee formation

- Drafting and consensus

- Public consultation

- Formal approval and publication

- Adoption by national standardization bodies

This is not an exact process, and it could change depending on the specific sector, country, or standard in question. Also, it could take years for standards to take their final form. Often, in conjunction with the ISO and the IEC, either one of the European standards organizations CEN or CENELEC will collaborate in the process to help ensure consistency and interoperability of the standards developed.

5 Why is standardization a good thing?

At first, we might think standards are there to simply make sure things are manufactured correctly. This is certainly true, but there are other reasons as well. Taking a macro view of competitiveness, standards will play a critical role in enabling industries to face current challenges.

The EU is concerned with ensuring European leadership in global standards, making standardization a driver of European competitiveness and resilience. For example, standards play a role in supporting programs in the green and digital transitions.

The same could be said of US and British standards, whose coordination bodies are also trying to drive their own competitiveness. Different nations might compare or consolidate their national standards for trade and other purposes, but no more.

As students of Functional Safety in general and standards specifically, it should be heartening to know that the EU goes to some lengths to promote more academic awareness of standards and good practices. This is to ensure that there is a pipeline of standardization experts in the future.

6 The role of national standards

If standards across national bodies were not managed closely, the diversity would be unmanageable. In the EU, there is a concerted effort to produce most standards as a European, or EN standard, which is then passed down to each country’s national level. In practical terms, this would mean that the EN standard is declared a national standard once it is adopted by each member country.

For example, in Germany, the national institute for standardization, DIN, coordinates national standards. The standards it produces are known as DIN standards. It is commonplace for DIN standards to be developed in close collaboration with CEN or CENELEC. The resulting standard, which is a European standard adopted in Germany, is now called DIN EN.

Figure 10: Deutsches Institut für Normung is the national institute for standardization in Germany

Source: Adobe Stock

Similarly, if a European standard is developed with the help of the ISO, it becomes known as EN ISO once accepted by CEN or CENELEC, and when it is adopted in Germany, it becomes known as DIN EN ISO. In other European countries, the process is identical except that a different institute publishes the standard.

6.1 Examples of national standardization Organizations Worldwide

We might think that as standards are so important to safety in everyday life, our globalized marketplace would be striving towards the same global standard. This is not the case, and standardization processes vary wildly across key economies. In this section, we will discuss the situation with standards in selected countries outside of Europe.

6.1.1. USA

In the US, individual states play a major role in setting and monitoring standards. Equipment cannot be commissioned before it receives special approval from officials at the state, county, or municipality level. Inspectors at these various levels have jurisdiction over installations in their location and are the only entities allowed to grant the approval of electrical building and machine safety.

However, the Occupational Safety and Health Administration (OSHA) is still a very important entity in the US as far as safety goes. This sub-agency of the US Department of Labor has a mandate that involves defining and monitoring basic health and safety measures in the USA. This body is responsible for publishing and monitoring the well-known OSHA minimum requirements and standards.

Another level of oversight comes from selected accredited drafters that can develop and publish standards. These are usually manufacturers’ associations. Some of the best-known of these include:

- American National Standards Institute (ANSI)

- National Electrical Manufacturers Association (NEMA)

- National Fire Protection Association (NFPA)

6.1.2 Japan

Japan largely adopts the IEC and ISO standards as national Japanese Industrial Standards (JIS). The Japanese Industrial Safety and Health Law issues standards meant for design specifications concerning selected machinery and equipment such as cranes and lifts. It should be noted that the Industrial Safety and Health Law does not directly refer to each JIS standards, meaning there is no legal obligation to apply and implement the JIS standards.

Local governments, such as prefectural and municipal governments, also play a role in ensuring safety standards within their jurisdictions. They may have specific responsibilities for areas like public health, fire safety, and building codes. They are known to encourage work to be conducted according to JIS standards.

6.1.3 China

China's independent national standards system is known as the Standardization Administration of China (SAC). For the most part, the SAC usually adopts international ISO and IEC standards, in many cases only with slight deviations. This entity also issues what are known as the national GB or GB/T standards.

- GB - Guobiao, which means ‘national standard’.

- GB/T - Guobiao/Tujiàn, which means ‘recommended national standard’.

The country also uses the State Administration of Work Safety to define and monitor health and safety measures. Monitoring is carried out by local health and safety inspectors. In May 2022, China rolled out its own Chinese certification system – Chinese Compulsory Certificate (CCC).

7 EN engineering safety standards

There is not enough room in this chapter to provide a full and complete list of all the European Functional Safety and engineering safety standards. The Machinery Directive alone has some 760 standards harmonized under it. In this section, we will discuss some of the main standards pertinent to electrical safety.

Figure 11: International safety standards

Source: HIMA Paul Hildebrandt GmbH

Some commonly recognized standards include:

7.1 IEC 61508

This is a widely adopted international standard that provides a generic framework for Functional Safety across different industries and applications. As such, it is also referred to as the umbrella standard. It is independent of any application and is mainly used by manufacturers. IEC 61508 covers the Functional Safety of electrical/electronic/programmable electronic safety-related systems.

7.2 ISO 26262

This standard specifically focuses on Functional Safety in the automotive industry, providing guidelines for the development of safety-critical electrical and electronic systems in vehicles.

7.3 IEC 61511

This standard addresses Functional Safety for the process industry, providing guidelines for the implementation of safety instrumented systems (SIS) in the process sector. As a sector standard of EN 61508, it is a sister standard of EN 62061, which covers machinery, and EN 61513, which covers the nuclear industry. This is reflected in the similar observations and mathematical principles contained in the three standards.

The most recent edition of the IEC 61511 standard is Edition 2, was published in 2016, but as we have indicated, was not initially accepted by CENELEC. It took one Corrigendum, released in 2019, to become an IEC EN DIN 61511, Edition 2. It is entitled Functional Safety - Safety instrumented systems for the process industry sector. Compared to earlier editions, IEC 61511 Edition 2 introduced several new terms and updated definitions to clarify certain concepts and align with other industry standards. Some errors and inconsistencies were corrected and there were improved with harmonized definitions with IEC 61508.

8 Case study: Hexion success story

Formalin is the aqueous solution of formaldehyde. This chemical substance is used in large amounts in a variety of chemical manufacturing processes. Some common products that rely on formalin as a key manufacturing input include urinary antiseptics, resins for the tanning industry, and treatments for vegetable proteins in food production. Concentrated formalin is a colorless, flammable gas with a strong pungent odor. It is extremely irritating to the mucous membranes of humans and animals.

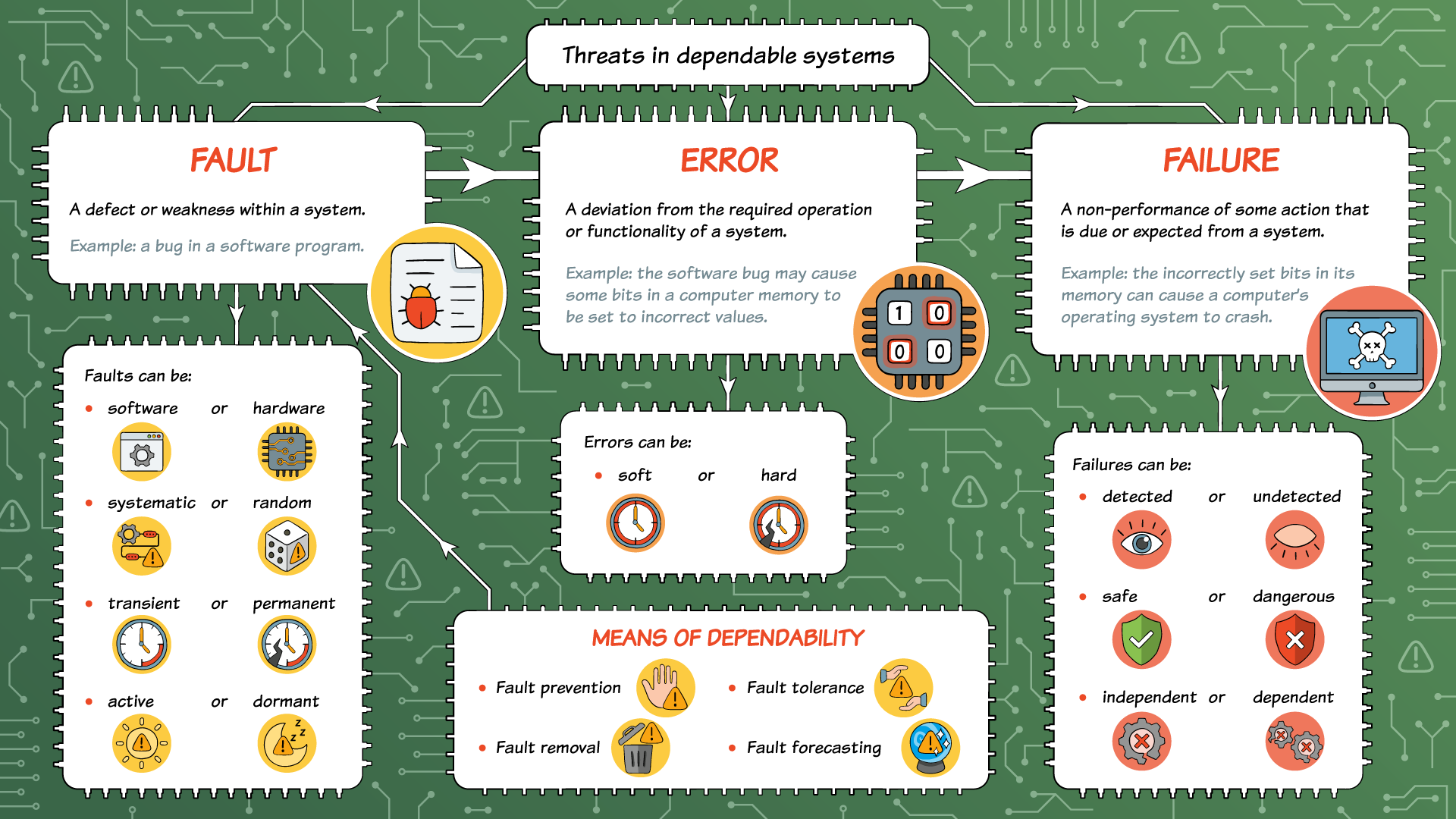

HIMA was contracted to provide safety services to major formalin producer Hexion. During formalin production gaseous by-products are produced in addition to the desired main product formaldehyde. This gaseous by-product stream is an explosive mixture consisting mainly of hydrogen and nitrogen in addition to traces of organic compounds.

Figure 12: Formalin by-products include an explosive mixture consisting mainly of hydrogen and nitrogen

Source: Adobe Stock

HIMA's task was to modernize Hexion’s thermal oxidizer system and to implement a high level of safety: A programmable Safety Integrated Level (SIL) 3 controller that would ensure compliance with the safety requirements for the plant. HIMA was also called upon to implement boiler protection, control an inclusive burner management system, and to ensure residue combustion including steam generation with a heat recovery steam generator.

This challenging project included the rebuild of instrumentation, safety, and process technology. The HIMA application team would be involved in the project from the concept phase through the Hazardous Operations (HAZOP) and Safety Requirement Specification (SRS) system design and programming phases to the commissioning and optimization phase.

Imagine you were an engineer working for HIMA. How would standards related to EN 61511, which is the applicable standard for the process industry, affect how you work and what you do?

We can suggest guidance as follows. Before HIMA can commission the formalin-making plant, several steps and considerations should be considered if HIMA is to abide by the law:

8.1 Safety Requirements Specification (SRS)

According to EN 61511, you must develop a comprehensive SRS that outlines the safety requirements for the formalin plant, including identifying the hazardous scenarios. You must formulate risk reduction targets and specify the safety functions that the SIS should perform.

8.2 Safety lifecycle

You must implement the safety lifecycle approach as described in EN 61511. This involves going through different phases, such as hazard and risk assessment, design, installation, operation, and maintenance.

8.3 Design and Implementation

You must ensure that the SIS design aligns with the requirements outlined in the SRS. This includes selecting appropriate safety instrumented functions, determining required Safety Integrity Levels (SIL), and designing the safety system architecture.

8.4 Functional Safety assessment (FSA)

You must conduct FSAs throughout the commissioning process to assess and verify that the SIS meets the specified safety requirements.

8.5 Testing and validation

You must conduct FSAs throughout the commissioning process to assess and verify that the SIS meets the specified safety requirements.

9 Current challenges in the implementation of Functional Safety standards

As we have seen, standards have real-world implications that serve a very important function. As students of safety and of the standards that underpin safety frameworks, it is important to have a holistic view of the study area. Applying standards is not a trouble-free process. These are some of the present challenges in the implementation of standards worldwide:

9.1 Complex regulatory landscape

As we have seen, the EU has the difficult task of aligning the safety activities of several organizations at international, regional, and national levels. This work is complex and time-consuming for organizations, especially those operating in multiple industries that require adherence to different safety standards simultaneously.

9.2 Competence and expertise

There is a need for a greater number of qualified professionals with expertise in Functional Safety to ensure effective implementation and compliance. Organizations often face challenges in findi individuals with the necessary skills and experience to perform safety-related tasks.

9.3 The arrival of artificial intelligence

With the increase in intelligence-infused machines, standards must be revised to cater to matters like social responsibility dimensions. While governments are relaxing their grip on safety protection regulations by replacing restrictive technical laws with goal-oriented legislation, intelligent machines need standards that give thought to ethical and social responsibility questions. As we have discussed in the formulation of standards, as long as there are no rules or guidelines or standards for artificial intelligence, all parties can continue unhindered.

Conclusion

The role of standards in ensuring safety cannot be understated. Standards help strengthen safety frameworks and give concrete direction to role players within the safety ecosystem. Standards cannot be crafted and evolved without the considerable knowledge and skill of technical experts. The process of bringing standards to life is laborious and time-consuming. However, this important work must continue if we are to ensure that the equipment and systems which make modern societies livable can perform predictably and safely.

Sources

[1] "B. Standardization processes," eLearning Platform. [Online]. Available: https://www.standardspluselearning.eu/b-1-1-standardization-organizations

[2] "Controlling thermal oxidizer," Jun. 20, 2004. https://www.hima.com/en/industries-solutions/References/success-stories/Controlling%20Thermal%20Oxidizer%20%2004-06-2022

[3] "Homepage." https://www.iec.ch/homepage

[4] "IEC 60050 - International Electrotechnical Vocabulary - Welcome," IEC - International Electrotechnical Commission. https://www.electropedia.org/

[5] "ISO - International Organization for Standardization," ISO. https://www.iso.org/home.html

[6] "Legal and normative bases for technical documentation." https://www.technical-communication.org/technical-communication/important-standards-in-technical-communication/legal-and-normative-bases-for-technical-documentation

[7] "Standards and the law," Din-en. https://www.din.de/en/about-standards/standards-and-the-law

[8] "Summaries of EU legislation - EUR-Lex." https://eur-lex.europa.eu/browse/summaries.html?locale=en

[9] "Types of legislation | European Union," European Union. https://european-union.europa.eu/institutions-law-budget/law/types-legislation_en

List of standards

[10] Functional safety - Safety instrumented systems for the process industry sector - Part 1: Framework, definitions, system, hardware and application programming requirements, IEC 61511-1:2016.

[11] Functional safety - Safety instrumented systems for the process industry sector - Part 3: Guidance for the determination of the required safety integrity levels, IEC 61511-3:2016.

[12] Standardization and related activities — General vocabulary, ISO/IEC Guide 2:2004.