SAFETY LIFECYCLE MANAGEMENT

Improved performance through digital transformation

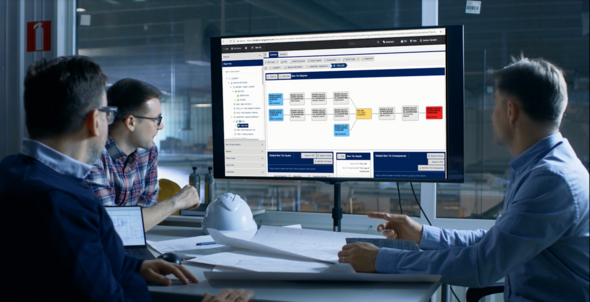

Process safety and functional safety are more than just the use of hardware and software, or the use of testing and metrics. Taking an overall approach and instilling a culture of safety requires a complete end-to-end system. This includes digitalized lifecycle management, from initial Hazard Analysis through operations and maintenance to final decommissioning

HIGHLIGHTS

Holistic Safety Lifecycle Apporach

AT A GLANCE

Rely on Lifecycle Management Digitalization from HIMA

-

Standards-CompliantWith lifecycle management solutions from HIMA you meet the requirements of IEC61511 and IEC61508.

-

Digital TransformationThe elimination of the silo culture of accessing, storing and requesting information, which on many occasions will be out of date.

-

Cost SavingImplementing an end-to-end 100% compliant functional safety management concept, we will minimize the costs

-

AnaylsisSLM will provide real field data analysis compared to theoretical calculations

Your HIMA Contact