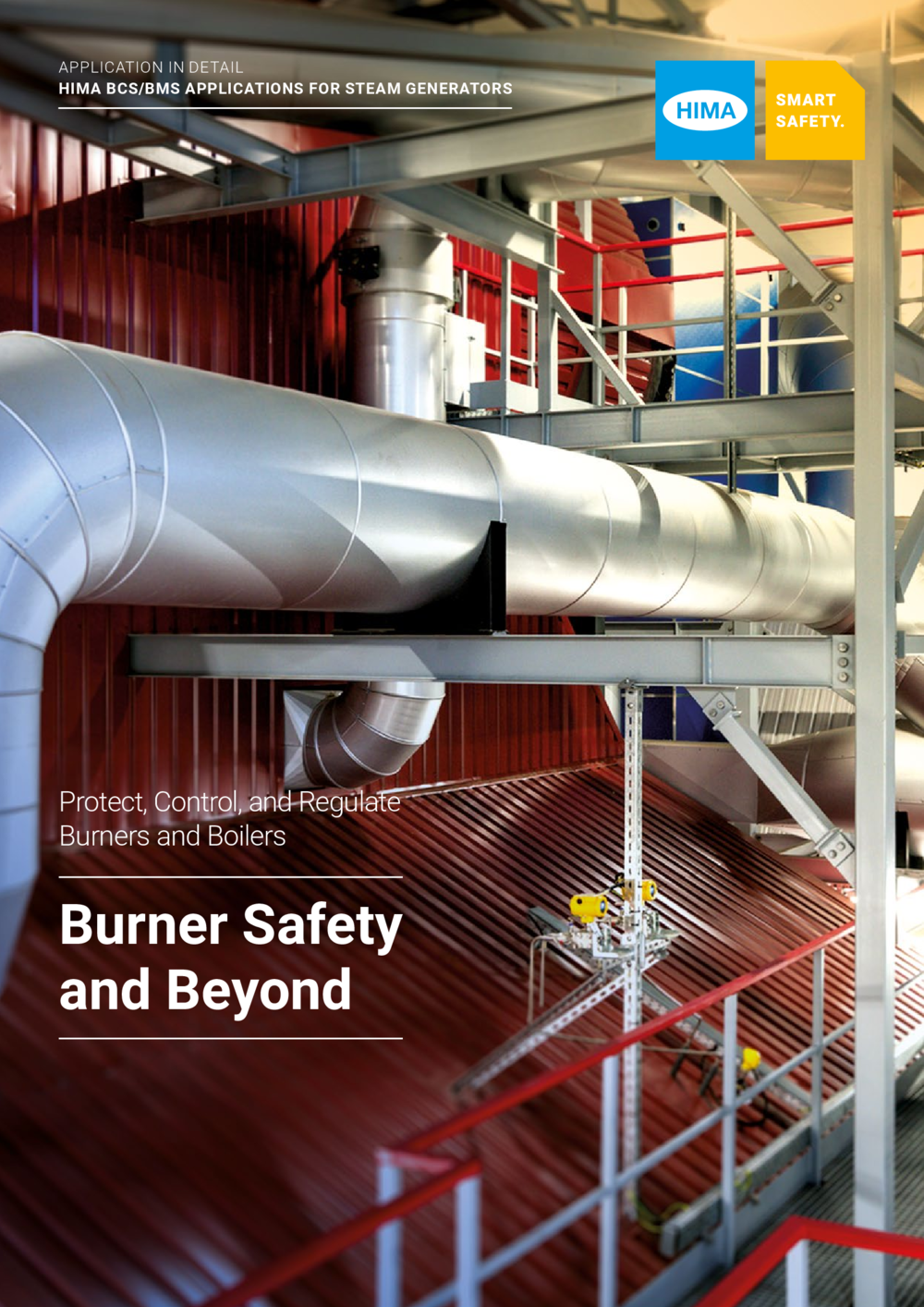

HIMA BCS: Combined Control for Burners and Boilers

Countless furnaces are in operation around the world today. However, most of them have an out-of-date burner control system running in the background. In the best case scenario, this only means your technicians must perform unnecessary additional tasks. In the worst case scenario, serious danger may occur. Protect yourself against such situations with a universal system for safety and critical control. This enables you to not only control your burners and boilers, but also to automatically stabilize and regulate industrial furnaces so that they function at optimal operating conditions.

Here's How HIMA BCS Works

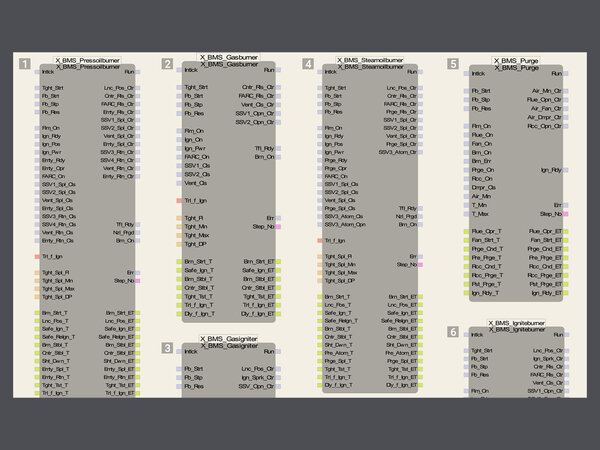

Traditional burner controls are no longer sufficient in times of increasingly strict safety standards and environmental regulations. Those who are responsible for thermal processes and steam generators also need systems for furnance regulation and boiler protection. This may sound like additional effort, but it can actually make processes more efficient. With the HIMA BCS application you maintain full control of all system components. But what does this exactly mean? Temperature, pressure, mass flow and volumetric flow rates, and furnace performance are automatically adjusted to the ideal operating conditions and stabilized. This ensures that you maintain maximum availability of your facility.

HIMA BCS application is configured for multi-burner systems and multi-fuel burner systems. A wide variety of fuels or residual materials can be obtained in combination through combustion air. This saves your engineers valuable maintenance and repair time while lowering operating costs. Additional system components are not required.

Centralized operation and observation of the firing process is supported by extensive and powerful communication interfaces and protocols.

HIMA BCS application is drawn from the many years of experience of HIMA's application engineers. They are experts in the field of safety technology, and they also have expert knowledge of the required standards in the process industry. Regardless of the purpose for which you use the HIMA solutions: You can always be sure that all applicable regulations are complied with.

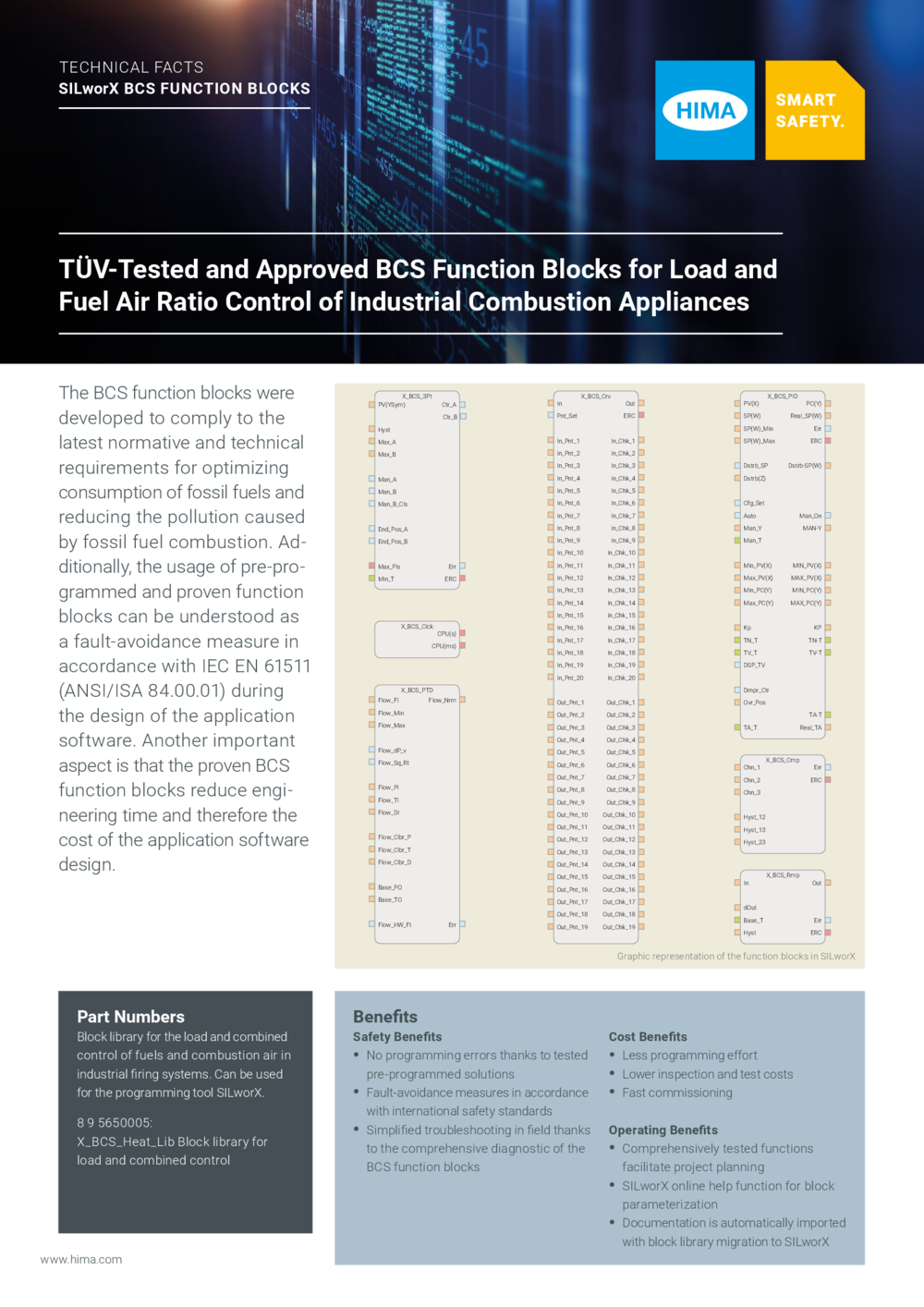

In addition, each individual function block of HIMA BCS application has been tested and approved by TÜV, for example: fuel-air monitoring. This makes it easy to gain approval for your individual safety system.

Cybersecurity has become an essential component of industrial safety. An event that triggered this was when a German steel mill was attacked by hackers a few years ago. The attackers were able to manipulate a blast furnace and cause serious damage.

With HIMA safety controllers such attacks haven't got a chance, because HIMA safety controllers run independently of the process control system. Hardware and communication are physically separated.

Moreover, all program sections and running processes can be safeguarded individually with passwords, and adapted individually without repercussions for the rest of the safety control system.

This has been certified by the renowned Achilles Certification.

With over 50 years of experience in industrial safety, HIMA has established itself as a market leader. We have successfully completed many BCS projects for customers around the world: ranging from thermal processing systems for furnaces and burners to steam boilers for burners and boilers.

BCS References

- BASF, Germany

- BK Guilini, Germany

- Kopf-Holding and eggs Engineering/ enduser Grillo AG, Germany

- OMV, Germany

- Emerson/Westinghaus, China

- Azko Nobel/ Enduser Clauss Ofen, Germany

- Lanxess, Germany

- Loesche/ Enduser HGE OITA Coal, Japan

- Loesche, Germany

- Outotec, India

- Phillips 66, USA

- ExxonMobil, USA

Traditional burner controls are no longer sufficient in times of increasingly strict safety standards and environmental regulations. Those who are responsible for thermal processes and steam generators also need systems for furnance regulation and boiler protection. This may sound like additional effort, but it can actually make processes more efficient. With the HIMA BCS application you maintain full control of all system components. But what does this exactly mean? Temperature, pressure, mass flow and volumetric flow rates, and furnace performance are automatically adjusted to the ideal operating conditions and stabilized. This ensures that you maintain maximum availability of your facility.

HIMA BCS application is configured for multi-burner systems and multi-fuel burner systems. A wide variety of fuels or residual materials can be obtained in combination through combustion air. This saves your engineers valuable maintenance and repair time while lowering operating costs. Additional system components are not required.

Centralized operation and observation of the firing process is supported by extensive and powerful communication interfaces and protocols.

HIMA BCS application is drawn from the many years of experience of HIMA's application engineers. They are experts in the field of safety technology, and they also have expert knowledge of the required standards in the process industry. Regardless of the purpose for which you use the HIMA solutions: You can always be sure that all applicable regulations are complied with.

In addition, each individual function block of HIMA BCS application has been tested and approved by TÜV, for example: fuel-air monitoring. This makes it easy to gain approval for your individual safety system.

Cybersecurity has become an essential component of industrial safety. An event that triggered this was when a German steel mill was attacked by hackers a few years ago. The attackers were able to manipulate a blast furnace and cause serious damage.

With HIMA safety controllers such attacks haven't got a chance, because HIMA safety controllers run independently of the process control system. Hardware and communication are physically separated.

Moreover, all program sections and running processes can be safeguarded individually with passwords, and adapted individually without repercussions for the rest of the safety control system.

This has been certified by the renowned Achilles Certification.

With over 50 years of experience in industrial safety, HIMA has established itself as a market leader. We have successfully completed many BCS projects for customers around the world: ranging from thermal processing systems for furnaces and burners to steam boilers for burners and boilers.

BCS References

- BASF, Germany

- BK Guilini, Germany

- Kopf-Holding and eggs Engineering/ enduser Grillo AG, Germany

- OMV, Germany

- Emerson/Westinghaus, China

- Azko Nobel/ Enduser Clauss Ofen, Germany

- Lanxess, Germany

- Loesche/ Enduser HGE OITA Coal, Japan

- Loesche, Germany

- Outotec, India

- Phillips 66, USA

- ExxonMobil, USA

How HIMA BCS Benefits Plant Operators

-

Highest Level of ComplianceNational and international standards are continuously complied with, and future developments are also taken into account.

-

More ControlYou control, regulate, and protect your complete facility with a single system.

-

Long-Term InvestmentThe system runs without interruption over the entire lifecycle.

-

Reduced Fuel ConsumptionCombined control is more cost-efficient and lowers pollutant emissions.

-

Easy OperationThanks to high performance communication interfaces and protocols.

Your HIMA Contact

The specialized HIMA application engineers for burner management and burner control draw up a precisely tailored safety concept together with you – and implement it in compliance with the highest standards of quality.