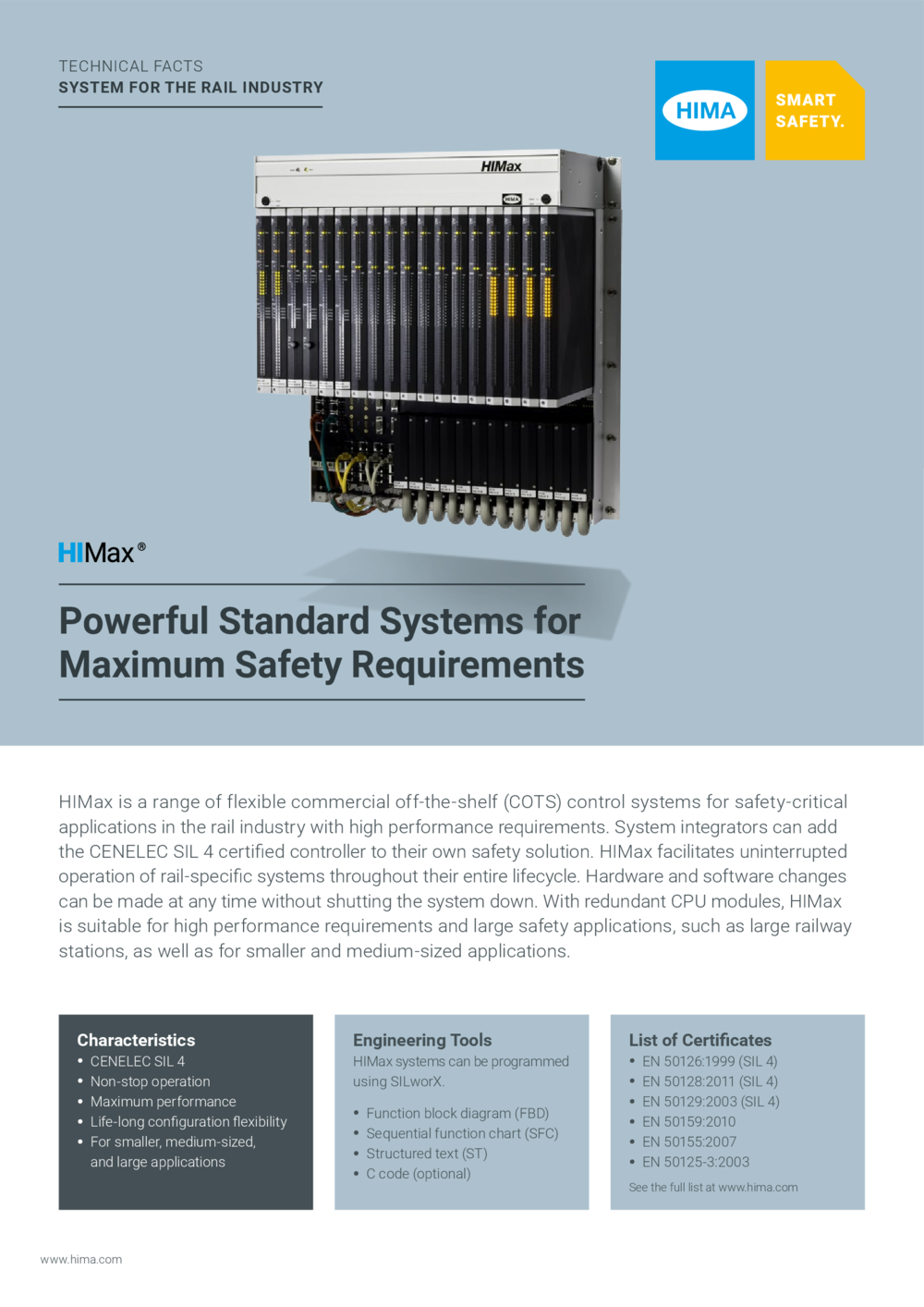

COTS: Standard Systems for the Strictest Safety Requirements

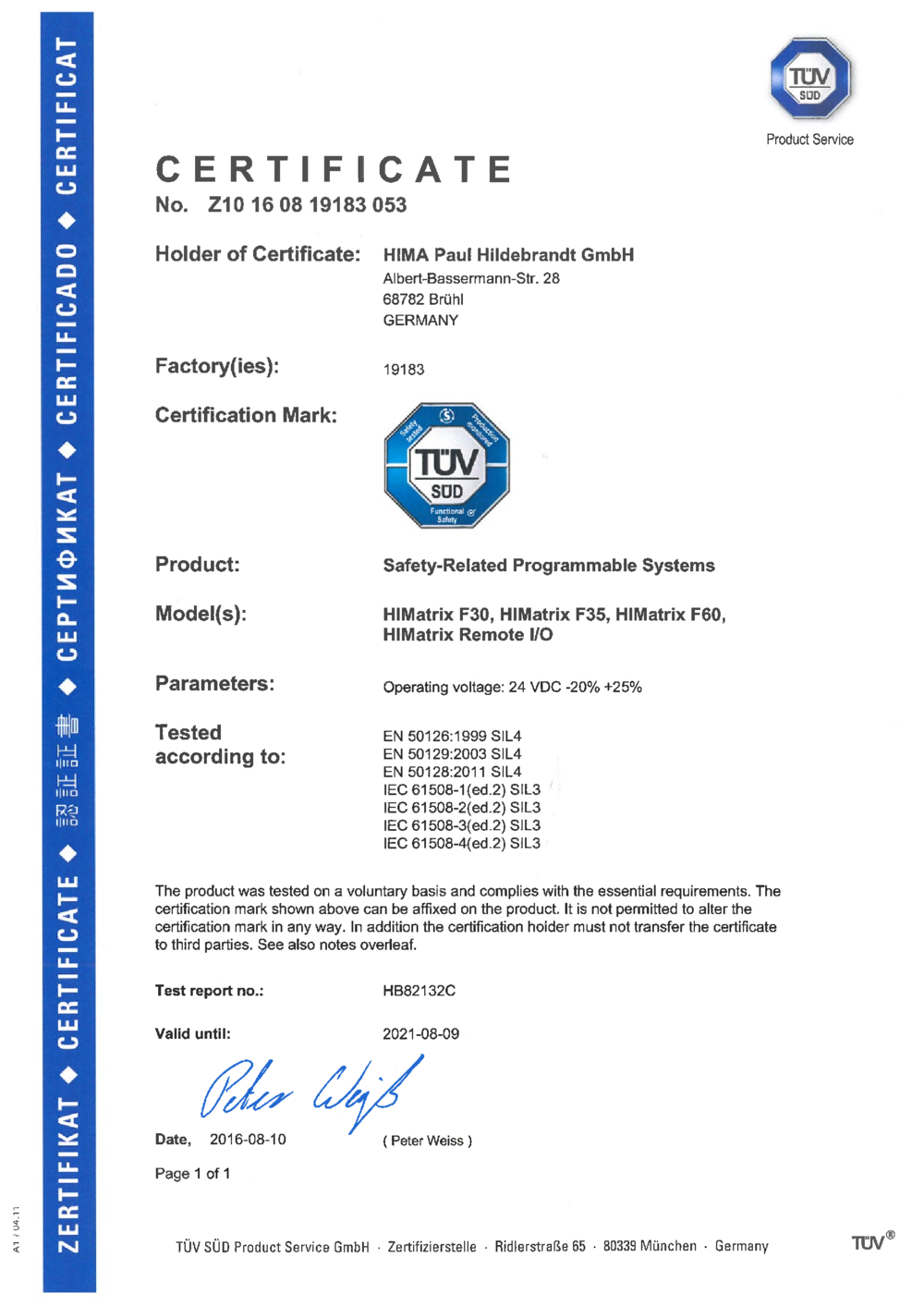

For decades, railway companies in particular have had to turn to expensive, proprietary solutions in order to meet legal requirements. However cost pressure and dangers are on the rise – and this old model no longer works. The solution? Commercial-off-the-shelf (COTS) products. HIMA COTS controllers comprise standard components and can therefore be produced, sold, and operated at significantly lower cost. They can be implemented immediately, with no need for customization, and extended as needed. As supplied, they fulfil even the strictest safety and security standards and are approved for SIL 4 application in accordance with CENELEC.

How HIMA COTS Solutions Work

How You Benefit from HIMA COTS Solutions

-

Cost-EffectiveHIMA controllers are mass produced and can be used without adaptations.

-

High-PerformanceEasy installation, fast data transmission.

-

Future-ProofThanks to their modular design, the systems can easily meet future requirements.

-

Easy-to-UseThe controllers are based on proven standard components and only contain the functions that you really need.

-

FlexibleYou can scale your safety system as desired at any time.

"I believe that, in the future, COTS solutions will be used for all security-related applications in smaller and medium-sized systems in the rail industry. Everything else is simply too expensive."

Your HIMA Contact

Our application engineers for the rail industry support you in every step of your safety project – regardless of whether you want to safeguard individual level crossings, trains or a large railway station.