Keeping Safety Systems and Control Systems Separated

Distributed control systems (DCS) are crucial for controlling and monitoring your plants. And because they are so important, you opted for a DCS from a specialist provider. Why not do the same when choosing a safety solution?

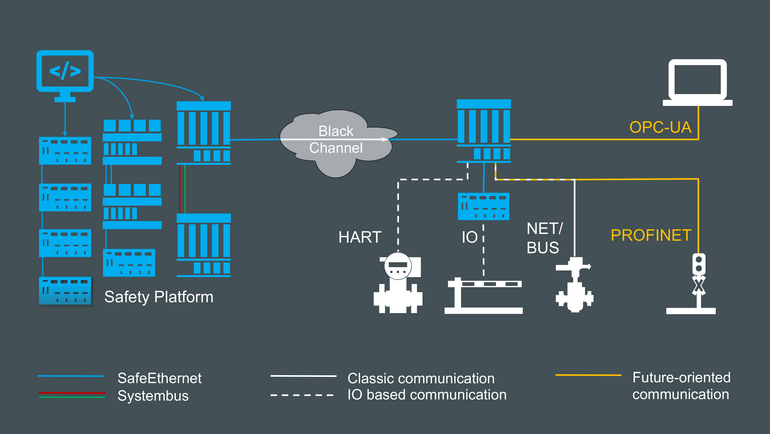

International standards strongly recommend separating control systems and safety systems from each other. This means you are only fully protected if your safety system comes from an independent provider that specializes in safety: like HIMA.

HIMA safety solutions run independently of your control system. Consequently, if an error occurs in the DCS, it cannot affect your safety system. Your safety system continues to run smoothly – and your plants remain completely protected.

DCS-Integration and Asset-Management

Independent Open Integration Have you ever seen a plant that only uses devices from a single manufacturer? Although this may be technically feasible, it generally makes more sense to weigh the options when choosing among the best products and selecting an appropriate variety of suppliers. Most crucial is ensuring that you can efficiently network, monitor and control your different components.

HIMA solutions support all major communication standards:

- Well known communication like PROFIbus, Modbus (TCP) or OPC Classic

- Advanced field communication with HART protocol

- Future-proof open communication with

OPC UA for communication to the controller and higher level

PROFINET/PROFIsafe for communication to the field Level

The introduction of Ethernet APL will open up a great deal of new potential in the field. Having more information with greater accuracy enables better protection, which in turn enhances the availability of the plant, improves its safety and security, and ultimately increases its productivity.

Unlike other providers, HIMA offers solutions that are more flexible and functional to accomplish the most challenging applications. Complex applications such as the partial stroke tests can thus be implemented entirely within the HIMA safety system.

HIMA offers numerous options for perfect integration solutions. Simply select the devices that are best suited for your application and implement your individual solution - Independent Open Integration.

How You Benefit from HIMA Integration Solutions

-

More SafetyControl systems and safety systems run physically separate, which considerably reduces the error rate.

-

Greater ControlYou control, regulate, and protect your entire plant with a single system.

-

UninterruptedHIMA safety systems can be altered, extended, and maintained during operation.

-

Increased OutputYou can fully exploit the productivity potential of your plants.

-

Low Initial InvestmentAdditional components are not necessary.

-

Seamless SafetyYour safety system remains intact, even if you replace individual control systems and components.

CONTROL SYSTEMS

Compatible with All Major Providers

Our integration solutions connect HIMA controllers to process control technology and the asset management systems from other vendors. Distributed control systems – an overview:

Integration of HIMA and ABB systems is possible via the following options:

- OPC UA

- Classic OPC

- PROFIBUS

- MODBUS TCP/RTU

Integration to:

- ABB 800xA

- ABB AC800M

- ABB Symphony+ Melody

- ABB Freelance

Any questions? The Open Integration Team would be happy to help. You will reach us via our global support.

Integration of HIMA and Emerson systems is possible via the following options:

- OPC A&E

- OPC DA

- PROFIBUS DP

- MODBUS RTU

- MODBUS TCP

Coupling references:

- Emerson DeltaV

Any questions? The Open Integration Team would be happy to help. You will reach us via our global support.

Integration of HIMA and the Foxboro IA system is possible via the following options:

- MODBUS RTU

- MODBUS TCP

- PROFIBUS DP

- OPC DA

Any questions? The Open Integration Team would be happy to help. You will reach us via our global support.

Integration of HIMA and Honeywell systems is possible via the following options:

- OPC A&E

- OPC DA

- PROFIBUS DP

- MODBUS RTU

- MODBUS TCP

Coupling references:

- Honeywell Experion PKS

Any questions? The DCS Competence Team would be happy to help. You will reach us via our global support.

Integration of HIMA and Siemens systems is possible via the following options:

- PROFIBUS DP

- OPC A&E

- OPC DA

- MODBUS RTU

- MODBUS TCP

Coupling references:

- Siemens PCS 7

- Siemens S7-400

- Siemens S7-300

- WinCC

Any questions? The DCS Competence Team would be happy to help. You will reach us via our global support.

Integration of HIMA into DNA Valmet systems is efficiently done via:

- Modbus TCP

- Direct UDP integration (using safeEDR)

Any questions? The DCS Competence Team would be happy to help. You will reach us via our global support.

Integration of HIMA and Yokogawa systems is possible via the following options:

- MODBUS RTU

- MODBUS TCP

- OPC DA

- OPC A&E

- PROFIBUS DP

Coupling references:

- Centum CS 3000

- Centum VP

Any questions? The DCS Competence Team would be happy to help. You will reach us via our global support.

The MAC concept

Do you work with a main automation contractor (MAC)? They can also give you advice concerning HIMA solutions. As an independent safety specialist, HIMA successfully cooperates with all leading MACs and DCS manufacturers around the world.

Your HIMA Contact

Do you have questions about HIMA solutions or services? Our sales experts look forward to receiving your e-mail or phone call.