Digitizing the plant with PROFINET and PROFIsafe – flexible, safe, future-proof

Increased digitization offers many ways to create your best customized solution:

- Ethernet proved its robustness, availability and universality in industrial environments and is considered to be the most flexible communication solution in automation technology

- Seamless integration into any automation environment offers the opportunity to use best-of-breed devices - one of the major product benefits of HIMA systems

- Digitization is the modern method to improve profitability of plants – over the entire lifecycle

HIMA bundles these advantages and expands its solution offering with the Ethernet-based protocols PROFINET (Controller) and PROFIsafe (Host). Benefit of increased plant availability and efficiency over the entire life cycle.

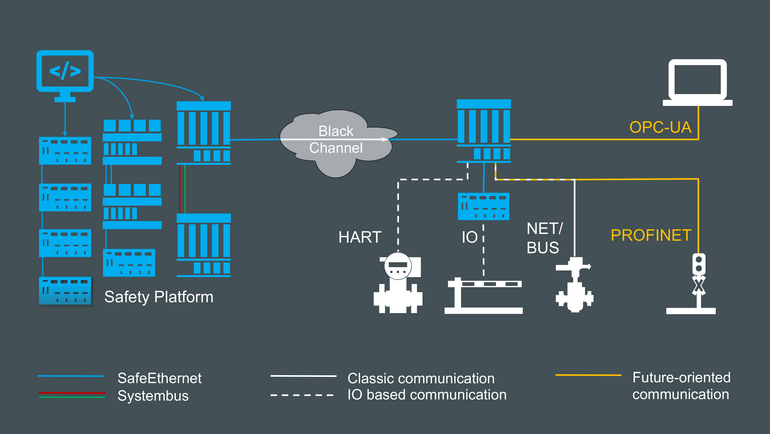

HIMA offers numerous options for integration into the field level. In addition to IOs and HART as well as other common bus systems and networks, PROFINET/PROFIsafe can now also be employed. The transfer of data to higher levels is implemented via OPC-UA.

Benefits of PROFINET/PROFIsafe during each phase of the lifecycle.

INSIGHTS in a minute

PROFINET - Digitalization down to the Field

PROFINET offers a perfect digitalization down to the field. In combination with Ethernet APL it helps to simplify safety processes.

Gain more insights about PROFINET.

PROFIsafe - Integration of Safety into your Network

Benefit from a complete, seamless solution by integrating safety devices from different manufacturers into safety PLC.

Learn more about PROFIsafe.

PROFINET communication with HIMax and HIMatrix

Together with its partner Softing Industrial, HIMA has developed a PROFINET controller based on FPGA. Learn more about the joint forward-looking development:

Profinews (English)

OpenAutomation (German)

Standard Ethernet is future-proof. It even enables visionary solutions like control in the field unified in one infrastructure for safety and non-safety, all while maintaining full separation and thus maximum security, availability, and safety. Establishing this concept consistently throughout the entire plant, gives you full transparency of data over the entire lifecycle. HIMA calls this concept the Independent Open Integration paving the way for future-proof automation solutions that combine minimum complexity and maximum cost- effectiveness.

HIMA Independent Open Integration always adapts to your individual requirements.

-

All in OneInfrastructure and devices combined in safety and non-safety

-

Fail-SafeResilient digital communication, incl. power supply in Ex Zone 2/1/0

-

Efficient OperationSolutions with minimum complexity and maximum cost-effectiveness

-

Future-proofStandardized, future-proof and high-performance solution

-

FlexibleVendor-independent, open and expandable technology

-

All in viewFull data transparency throughout the entire lifecycle

Your HIMA Contact

Do you have questions concerning HIMA solutions or services? Our sales experts would be pleased to respond to your email or your call.