Planar4: The SIL 4 Controller for the Highest Level of Security

Whether on an oil platform or in natural gas production, in some industrial sectors, even the smallest compromise is a compromise too many. Where the potential risk is extremely high, you require a safety controller that always runs error-free and that is resistant to cyberattacks. With the Planar4 system from HIMA, you benefit from a hardwired controller that is extremely robust and resilient. It also complies with relevant current standards. And it is the only controller that is approved for implementation up to SIL 4 in accordance with IEC 61508 Edition 2 (2010).

BENEFITS

Platform for the World's Most Critical Applications

-

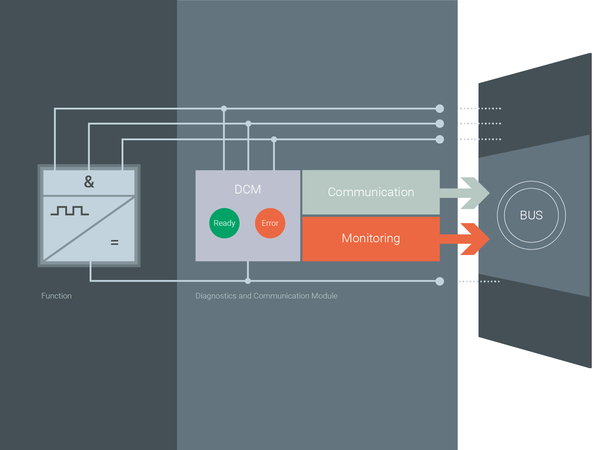

Highly RobustHighly Robust As Planar4 is hardwired, it is not programmed with software. This makes it extremely resistant to all kinds of errors.

-

Certified Safety up to SIL 4The Planar4 safety controller meets the requirements stipulated in the highest safety level SIL 4 in accordance with the international standard IEC 61508 Edition 2 (2010).

-

Extremely ResilientThe autonomous system is ideal for automation processes with an extremely high potential risk.

-

Full IT SecurityThe controller functions entirely without software. Consequently, successful cyberattacks are not only unlikely – they are physically impossible.

FEATURES

Nothing Is Safer

Your HIMA Contact

Do you have questions concerning HIMA solutions or services? Our sales experts would be pleased to respond to your email or your call.