ETHERNET APL

Industrial Ethernet acknowledged as the most flexible communication solution

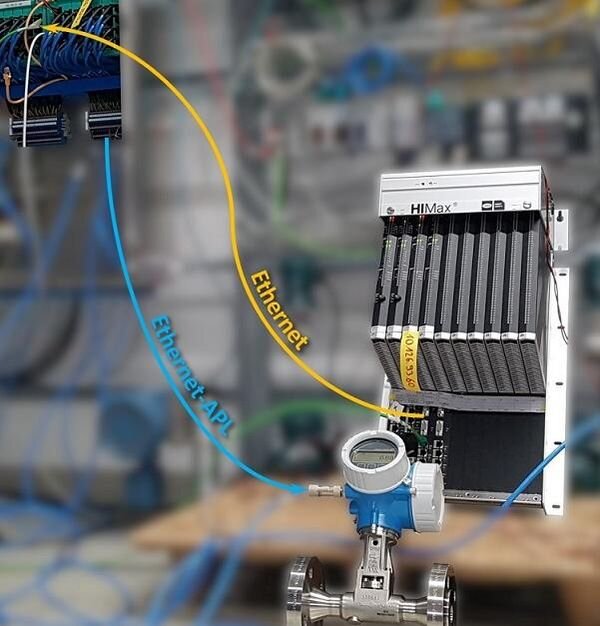

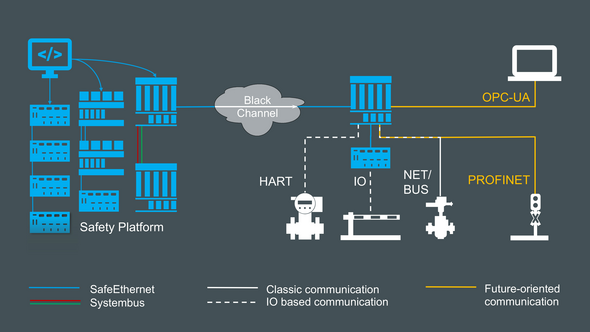

Ethernet APL has set out to replace the world’s leading analog 4…20 mA interface for connecting to field devices. On this front, standardized Ethernet communication offers significant cost and application advantages. Ethernet APL is on the leading edge supporting innovative network concepts. It provides a much wider bandwidth when compared to conventional fieldbuses, and complies with the requirements for Ex Zones 2/1/0, thus allowing for consistent digital communication throughout the entire plant. It opens up potential for innovative application scenarios such as offered by the NAMUR Open Architecture (NOA) and the second communication channel, which are extremely expensive or unaffordable for conventional transmission technology.

Industrial Ethernet is considered as the most flexible communication solution with proven resilience, availability and universality, while also being future-proof. Safety and non-safety are combined in one infrastructure by maintaining full separation, and therefore maximum safety, availability and security. Ethernet APL also enables visionary solutions such as control in the field and modular plants (MTP, modular type packages). By systematically establishing this communication infrastructure across the entire plant, complete data transparency is ensured over the entire lifecycle - Independent Open Integration.

Values and benefits of Ethernet APL

INSIGHTS in a minute

Ethernt APL - Safe Digitalization down to the Field

Ethernet APL supports innovative network concepts. Fully digitilize from the field into each level of the plant.

Increase functional safety with Ethernet APL.

From Data to Information

Ethernet APL offers significantly more extensive options due to the faster transmission in comparison to 4...20mA interfaces.

Benefit from real added value and learn more.

Ethernet APL Technology

-

All in OneInfrastructure and devices combined in safety and non-safety

-

Fail-SafeResilient digital communication, incl. power supply in Ex Zone 2/1/0

-

Efficient OperationSolutions with minimum complexity and maximum cost-effectiveness

-

Future-proofStandardized, future-proof and high-performance solution

-

FlexibleVendor-independent, open and expandable technology

-

All in viewFull data transparency throughout the entire lifecycle

Your HIMA Contact

Do you have questions concerning HIMA solutions or services? Our sales experts would be pleased to respond to your email or your call.