Digitalization of Functional Safety with Added Value

Functional Safety needs a digital transformation: #safetygoesdigital. This means not only automating existing processes, but also creating added value for companies.

Digitalized Safety and Security can reduce costs, increase plant availability, and provide optimization data. HIMA has a holistic approach for the Digitalization of Functional Safety.

Your Benefits

-

Holistic ApproachNo Safety without Security

-

SimplificationMaking demanding Functional Safety manageable.

-

FocusDigitalization of the essentials which create added value.

-

Flexible ArchitectureUsing the Independent Safety Plaform as a data hub.

Functional Safety – The Potential of Digitalization for Operators and EPC

The challenges regarding the digitalization of functional safety are faced by everyone. With the maxim "Digitalization of Functional Safety with Added Value", HIMA is bundling its activities to get one step closer to the future.

In this video Peter Sieber, Director Strategic Marketing of HIMA Group, explains the individual aspects of the #safetygoesdigital program and points out how customers will benefit.

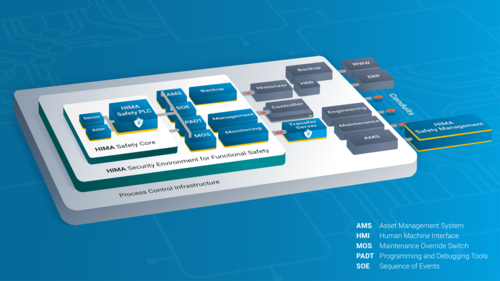

No Safety without Security

Safety and security are inextricably linked. Technologically, however, these areas must be strictly separated from each other. HIMA achieves this with the "Security Environment for Functional Safety", which maintains security throughout the entire life cycle of the safety solutions. This reduces complexity and lowers investment and operating costs.

Seamless Data Integration

HIMA Safety Engineering solutions support seamless data integration, from risk analysis throughout the engineering process to maintenance and retesting:

- Documenting all decisions

- Creation and implementation of detailed engineering

- Use of automatic test programs

- Creation of plant documentation meeting functional safety requirements

HIMA Safety Engineering reduces operating costs and increases plant availability and efficiency.

Streamline Engineering with HIMA Smart Safety Test

Data Becomes Usable Information

HIMA digitalization solutions support permanent compliance with standards and regulations by automatically transforming safety-relevant data into usable information. This helps to ensure compliance with the norms and standards that are vitally important for functional safety. Thus leading to increased empowerment for driving a continuous improvement process for functional safety. Such improvement will lead to reduced cost while achieving higher productivity.

Make Processes more Efficient

HIMA solutions enable more efficient processes in the following areas:

- Review of existing asset inventory (hardware and software).

- Detailed identification of changes

- Verification of changes

- Automated testing at the device level

- Review of the design basis of safety functions

Risks and costs for functional safety are minimized and plant availability is increased.

identify, verify and review changes? Find out more about it!

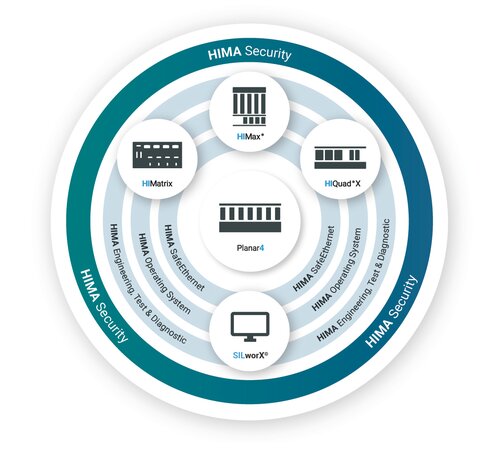

The HIMA Safety Platform

In the digital age, the number of risks is continuously increasing. It is difficult for plant operators to foresee correlations and consequences. We developed the HIMA Safety Platform – the world’s first scalable safety platform with built-in automation security.

#safetygoesdigital

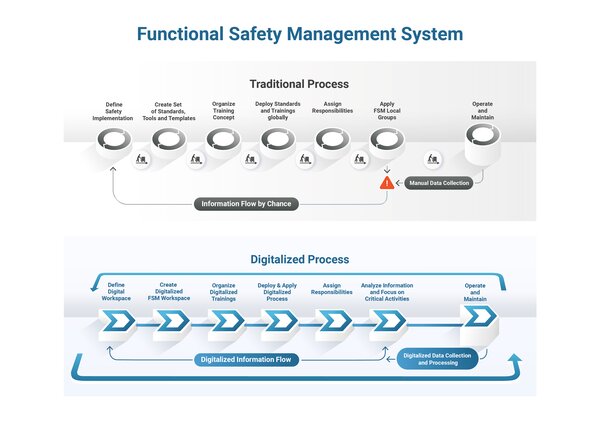

Exploiting the Potential of Safety Lifecycle Digitalization

Plant operators are facing challenges: shortage of skilled workers, internationalization, operating permits and pressure to increase productivity and efficiency. A new and holistic approach to digitizing the safety lifecycle now opens up new potential and helps to overcome the challenges. The technical paper compares the processes of a conventional and a digital Functional Safety Management System (FSM). Learn how you can achieve savings of up to 70% through digitalization.

Digitalization of Functional Safety: The Next Step in the Evolution of Your Processes

Read in this whitepaper why the digitalization of functional safety is an important step in the evolution of your processes. And why digitizing functional safety means not only improving the safety function, but also improving your processes overall.