HIMA TMC: Turbomachinery Control with Overspeed Protection

Around the world, the functional safety of turbines and compressors is becoming a focal point of industry. A small accident can have catastrophic consequences, endanger human lives, and incur high costs. The International Electrotechnical Commission reacts by introducing stricter safety standards – which can now be met with a single system for safety and critical control. HIMA TMC application ensures all turbomachinery runs safely.

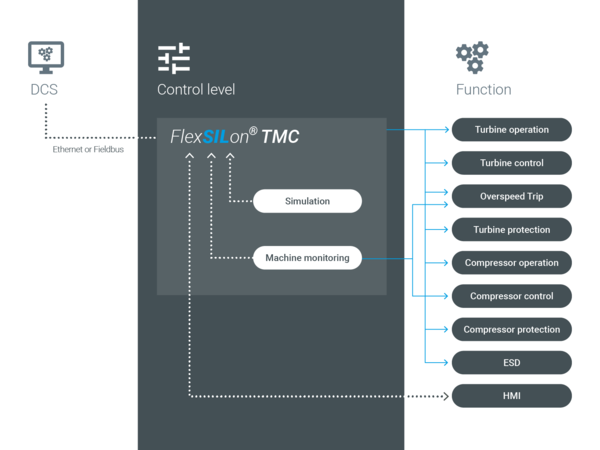

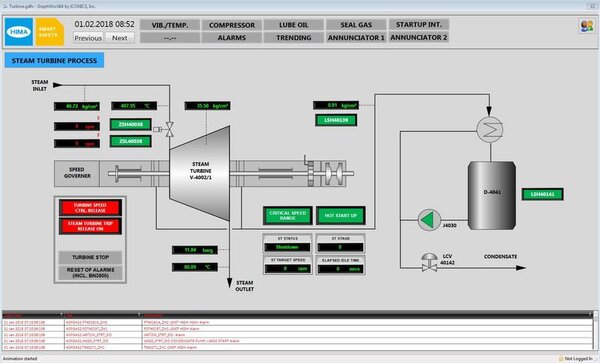

Here's How HIMA TMC Works

How You as an Operator of Turbomachinery and Compressors Can Benefit from HIMA applications

-

Reduce CostsReduce annual energy costs by up to six figures.

-

Cost-EfficientLower costs for each individual component.

-

Easy to IntegrateMinimal space requirements enabling integration into any environment.

-

Maximum ReliabilityMake your machines as reliable as possible.

-

Quick and EffectiveFast, easy commissioning and reduced maintenance requirements.

-

Total FlexibilityHigh investment security and compatibility.

"HIMA is noticeably driving turbine automation and control forward. The experts listen, take our concerns seriously, and understand our technical challenges."

Your HIMA Contact

For a new turbo machine, even in the planning phase, together with the customer HIMA engineers develop specific safety scenarios, optimized processes, and train personnel.