HIMA PMC: Pipeline Management Control with Leak Location

Each year, there are more than 2,000 incidents in the European pipeline network. Some involve financial losses. Others destroy the environment, plants, and perhaps the future of an enterprise. Safeguard yourself against such risks with an overall system for safety and critical control that detects even small leaks and precisely locates them – and which enables you to consistently control your gas or liquid pipelines. Learn more about HIMA PMC application.

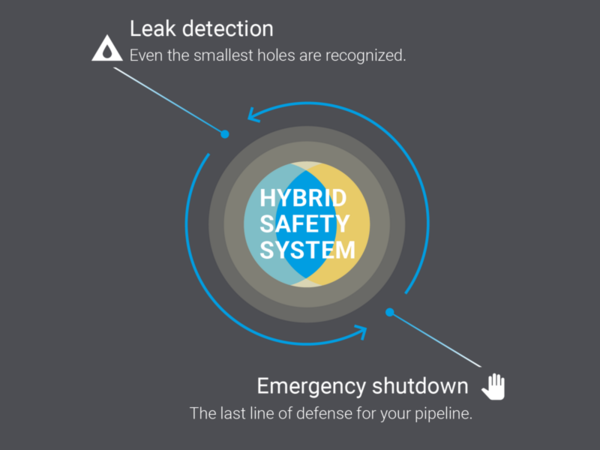

FEATURES

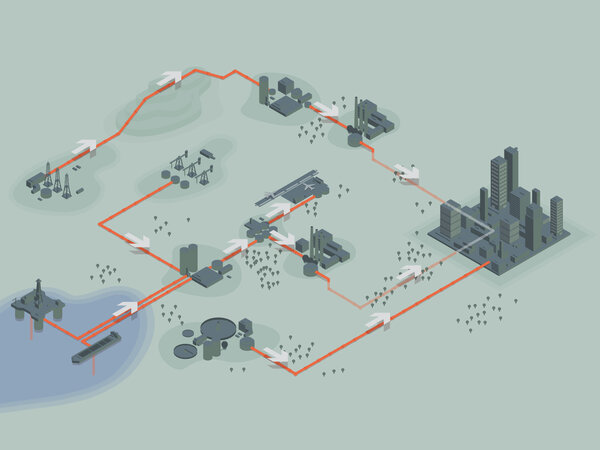

Here's How HIMA PMC Works

BENEFITS

How You Benefit from HIMA PMC as an Operator of Gas and Liquid Pipelines

-

Faster Fault RectificationThrough immediate and precise leak detection.

-

Maximum ReliabilityReduce environmental damage and the resulting claims.

-

High Security of InvestmentSystems can be adapted for use in the long term.

-

Increased ProfitabilityOperate pipelines safely, even at their limits.

-

More ControlEasier operation and maximum functional safety.

-

Easy CommissioningQuickly ensure uninterrupted operation over the entire lifecycle.

Your HIMA Contact

The specialized HIMA application engineers for pipeline management draw up a precisely tailored safety concept together with you – and implement it in compliance with the highest standards of quality.