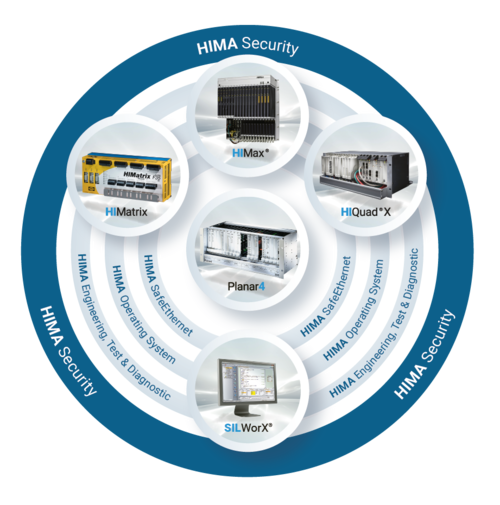

HIMA Safety Platform: Scalable and Cybersecure

In the digital age, the number of risks is continuously increasing. It is difficult for plant operators to foresee correlations and consequences. In this environment, how can you protect your plant for the future?

This is why we developed the HIMA Safety Platform – the world’s first scalable safety platform with built-in automation security. Additionally, it is the only platform that combines compact SIL 3 applications and highly complex, redundant solutions – offering less complexity in an increasingly complicated world.

The HIMA Safety Platform is especially stable and safe because the hardware and software are uniformly tailored to one another and combine to create a closed system. The components are:

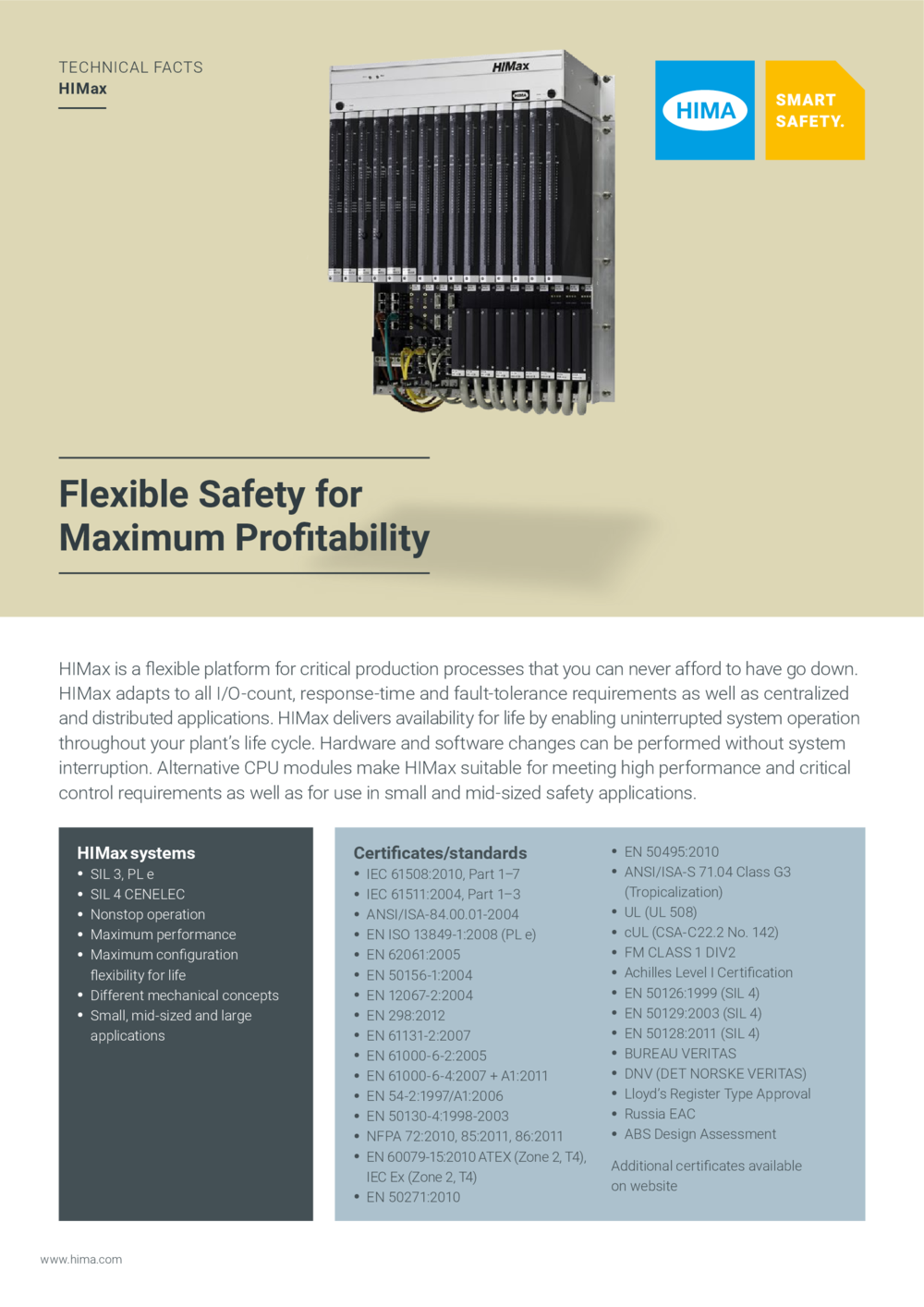

Hardware

HIMA experts support you in determining the best combination of proven HIMA safety controllers for your application.

Engineering Software

Our engineering tool SILworX enables you to develop your applications quickly and simply – reducing training costs.

Firmware

We use our own proprietary firmware in every HIMA controller. This minimizes risks equally in terms of functional safety and automation security.

Secure Communication

The SafeEthernet protocol connects all your HIMA systems securely – regardless of where they are.

Safer and More Profitable – Now and in the Future

-

Maximum SafetyEnsure the necessary level of safety is maintained for all installations.

-

Lower Operating CostsA single provider for software and hardware ensures lower costs and complexity.

-

Protection against CyberattacksHIMA’s operating system minimizes risks.

-

Flexible ApproachSwitching to the new model is simple and you can easily continue to use most existing HIMA controllers.

As Individual as Your Requirements

Your HIMA Contact

Do you need support with your HIMA system? The HIMA support organization is ready at any time – an email suffices.