SIL 4 safety system for disconnecting railway overhead lines

Maximum Safety for Italian High-Speed Train Tunnels

Underground structures through mountains and hills are among the most fascinating constructions of human engineering. But their operation is not without hazards. That's why the safe operation of tunnels deserves special attention. New systems for the safe isolation of overhead lines and their grounding create a new level of safety in the maintenance of tunnels and an emergency, as this Italian example shows.

Italy is the land of tunnels. This applies especially to rail traffic. Of the almost 16,800 kilometers of track in Italy, around 12,200 kilometers are electrified and a total of around 1,500 kilometers run through tunnels in the Alps, Apennines, and the like. Italy thus operates by far the longest railway tunnel network in Europe. The most important rail tunnels in Italy are several years old, such as the Simplon Tunnel (1906) in the Alps with a length of 19.8 kilometers and the 8.6-kilometer-long Mont Cenis Tunnel built in 1871. New underground links are being added all the time. Take for example, the 64-kilometer Brenner Base Tunnel, which is in the works for completion in 2028.

European regulations stipulate grounding

One aspect affects them all equally: Existing and future tunnels must adhere to European standards. The "Technical Specification for Interoperability (TSI) relating to Safety in Railway Tunnels (SRT)" is intended to achieve equal standards in European rail tunnels.

The technical specification for interoperability in European long-distance traffic was drawn up by the European Union in 2008 and updated in 2019. It formulates the technical requirements for rail tunnels to ensure the safety of passengers and staff. It covers communication and signaling systems and emergency evacuation procedures.

With the transposition into national regulations, the requirements and procedures for the design, construction and maintenance of railroad tunnels become concrete.

Automation system protects passengers and workers

For tunnels longer than a kilometer, it mandates a safe system for disconnecting overhead lines. Such a system is vital so that in an emergency, the rescue and care of injured persons can proceed as quickly as possible. In the event of an accident, it is not only the event itself, i.e. a derailment, fire or smoke, that poses a danger, but also the high voltage applied to the overhead lines.

In order to be able to evacuate quickly and safely while protecting both passengers and rescue workers, the rail operator must ensure that all overhead lines in the tunnel are disconnected from the grid and grounded before rescue services arrive. And just as important, that the entire area remains in a safe condition until the end of the work is completed.

STES, the safe earthing system

There are several types of earthing systems used in electrical installations. While emergency tunnel grounding used to be operated mechanically, integrated automatic systems are now state-of-the-art.

The new approach is to control corresponding disconnectors and thus the grounding of the overhead line in the tunnel.

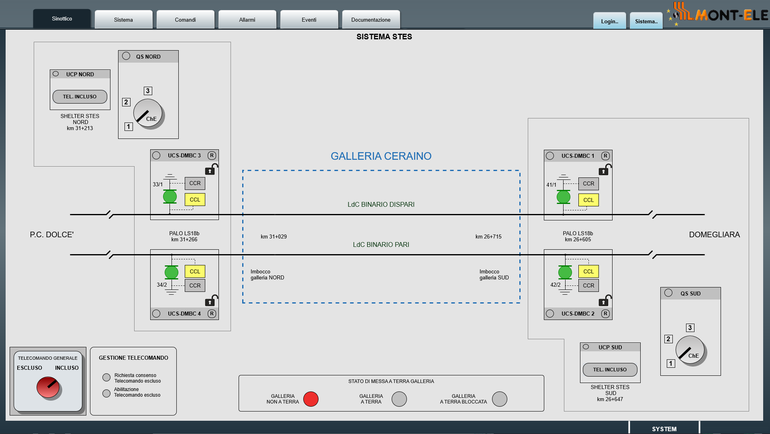

Such an automated and remote earthing control called STES (Sottosistema Trazione Elettrica di Sicurezza) has been developed by Mont-ELE in Italy. With its Railway Energy System, the electromechanical, electronic and automated systems manufacturer offers to safely disconnect and ground overhead lines of railroad lines in a centrally controlled manner and with the safety integrity level four, a life-saving safety system, especially in tunnels.

First footprint in high-speed tunnel

The STES system can be operated by a remote control center, and by a control and display unit installed on site. Installed by Mont-ELE, the first system is operated since more than 1 year in the Italian high-speed train tunnel “Galleria Ceraino” near Lake Garda, on the line from Verona towards Brennero. This installation in the 4 km long tunnel has a reference character for operator Italian railroad company RFI.

“As a partner of the operating companies, we strive to contribute to the safe and economical operation of the railroads and infrastructure. In addition to the highest level of safety. For us this also includes optimizing processes, for example during maintenance or repair,” says Andrea Vigano, project engineer at Mont-ELE. Thus, the largely automated system reliably prevents human error and reduces time-consuming activities on site. The operator not only benefits from an automatic safety system in an emergency: but the digital system is also advantageous for regularly occurring maintenance or repair work.

“Whereas our customers used to require manual intervention at each tunnel entrance and power line individually, our system now handles disconnection and grounding at the push of a button or turn of a key,” adds Vigano. The redundant and self-monitoring technology stores all historical processes in the SCADA and provides access to diagnostic, authorization and status information via the user interface.

-

Maximum safety and availability for tunnels with SIL-4 certified systems according to CENELEC

-

Easy integration of HIMatrix controllers and flexibly adaptation to customers' requirements

-

Integrated automatic systems for emergency tunnel grounding are now state-of-the-art

-

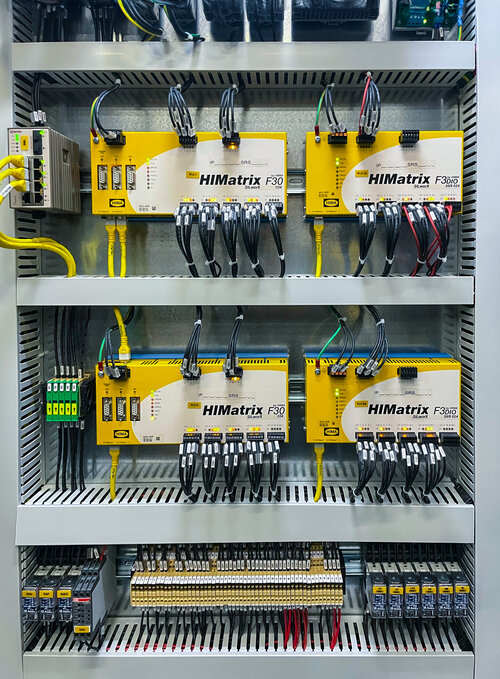

HIMatrix F30 controller built into the QS interface for safe status information transmission to other components

Safe processes certified up to SIL 4

Mont-ELE's fast safety grounding for overhead lines is available for different safety needs. In addition to a standard configuration, the company provides SIL-4 certified systems, according to EN 50126, EN 50128, EN 50129. To avoid tying rail customers to expensive, proprietary safety controllers, Mont-ELE wanted to use commercial-off-the-shelf solutions. The company found what it was looking for with HIMA. The safety specialist delivers off-the-shelf controllers, for the core safety functions of Mont-ELEs STES-System. Ex-factory, the HIMatrix controllers meet all safety and security standards and are approved for SIL 4 according to CENELEC. And the controllers are fast: The architecture behind HIMatrix enables responses, well below ten milliseconds.

"“As a partner of the operating companies, we strive to contribute to the safe and economical operation of the railroads and infrastructure. In addition to the highest level of safety."

“In addition to SIL 4 certification, an important decision criterion for us to rely on HIMA automation technology was that HIMatrix controllers can be easily integrated into our systems and flexibly adapted to customer requirements,” explains Vigano. This flexibility is expressed in different module sizes and scopes and in the option of being able to use numerous proven industrial network protocols. HIMatrix are intuitively programmed and configured using the SILworX drag-and-drop engineering tool.

Grounding disconnect switches installed in the “Galleria Ceraino” have the HIMatrix F30 controllers built into the QS interface. This interface relays the system’s safe status information to the other components via a redundant fiber optic network. In this way, the operating personnel on-site and in the control room are informed about the status of the electrical system at all times.

All components of the integrated automatic system have been approved by the Italian Railway Infrastructure Manager (RFI) and are certified CENELEC SIL4 in accordance with STES requirements for tunnel remote grounding systems control. Therefore, in all likelihood, Galleria Ceraino will not remain the last tunnel to operate with automatic safety grounding.

Pictures:

Header image: courtesy of Eugenio Merzagora (www.structurae.de)

Mont-Ele Srl. Italy

Your HIMA Contact